Thin Latex Gloves in Cleanrooms: Managing Tactile Precision, Protein Risk, and ISO Method Discipline

The Technical Vault

By SOSCleanroom

ISO 14644 Personnel Controls

Thin-Gauge Dexterity

Latex Protein Awareness

Change Frequency Discipline

Handling Precision

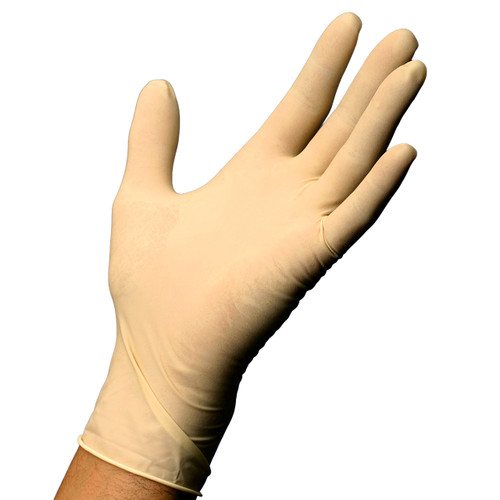

Cleanroom TGL900 Series 9.5 Latex Gloves — what thin latex gloves are designed to control

Cleanroom TGL900 Series 9.5 latex gloves are designed for cleanroom applications where

maximum tactile sensitivity and elasticity are required.

Natural rubber latex offers superior stretch and touch sensitivity compared to many synthetic materials,

which can be advantageous in precision assembly, inspection, and delicate handling tasks.

At the same time, latex introduces additional program considerations.

Thin-gauge latex gloves reduce the mechanical margin for misuse and require

heightened discipline around change frequency, solvent exposure, and personnel sensitivity.

Latex protein exposure and allergen risk must also be addressed through program controls,

training, and, where applicable, alternative glove options.

Operations takeaway: Thin latex gloves deliver unmatched dexterity—but only when protein risk,

integrity limits, and method discipline are clearly defined and enforced.

ISO-first context: glove material selection changes contamination and personnel risk

ISO 14644 identifies personnel as a dominant contamination source in cleanrooms.

Glove material selection directly influences particle generation, residue transfer,

and operator behavior. Latex gloves, particularly in thin gauges, are highly sensitive to

overhandling, abrasion, and solvent exposure.

USP-style operational thinking is useful when evaluating latex gloves:

if a method cannot be executed consistently across shifts due to discomfort,

sensitivity reactions, or premature glove failure, the process will drift.

Programs using latex should explicitly define when latex is appropriate and when

alternative materials are required.

Technical reference chart (confirm exact values via product page + manufacturer documentation)

| Product family |

Cleanroom TGL900 Series |

| Material |

Natural rubber latex |

| Thickness class |

Thin-gauge (9.5 mil class – refer to product page) |

| Primary control intent |

High dexterity hand protection for precision tasks |

| Sterility |

Refer to product page and packaging |

Program note: Latex gloves should be explicitly approved in SOPs due to allergen considerations.

Best-practice use (thin latex glove programs)

Best practice begins with task-based assignment.

Thin latex gloves are best suited for precision handling, inspection, and light assembly

where tactile sensitivity is critical.

Avoid using latex gloves for aggressive wiping, abrasive contact, or prolonged solvent exposure

unless the process has been specifically evaluated.

Don gloves using controlled technique and correct sizing.

Latex stretches easily, which can mask poor fit initially but increase fatigue and tear risk over time.

Operators should be trained to recognize early signs of thinning, tackiness, or surface degradation.

Define conservative glove change triggers.

Thin latex gloves should be replaced after contact with non-controlled surfaces,

after solvent exposure, after defined time intervals, or immediately if integrity is questioned.

Comfort should never justify extended wear beyond program limits.

Typical failures with thin latex gloves—and how to avoid them

- Protein sensitivity reactions: Prevention: screening, training, and approved alternatives.

- Premature tearing: Prevention: restrict latex to low-abrasion tasks.

- Residue transfer after solvent work: Prevention: aggressive change rules.

- Unapproved material substitution: Prevention: explicit SOP approval for latex use.

- Inconsistent handling outcomes: Prevention: standardized glove selection by task.

Suggested companion products and technical rationale

Thin latex glove programs benefit from tools that reduce direct hand contact

and limit extended wear during cleaning and inspection tasks.

Disclaimer

This Technical Vault content is provided as supplemental operational guidance only and does not replace

manufacturer instructions, facility SOPs, validation protocols, occupational health requirements,

or regulatory obligations. Always follow applicable ISO standards and site-specific procedures.

Refer to current manufacturer documentation for glove composition, sterility, and protein content.

Control substitutions and document receiving/lot traceability where required.

Questions? Email Sales@SOSsupply.com or call (214) 340-8574.

© 2026 SOSCleanroom. All rights reserved.