Thin Nitrile Gloves in Cleanrooms: When Reduced Thickness Improves Control—and When Discipline Must Increase

The Technical Vault

By SOSCleanroom

ISO 14644 Personnel Controls

ISO 5 / ISO 6 Operations

Thin-Gauge Tactile Control

Handling Precision

Change Frequency Discipline

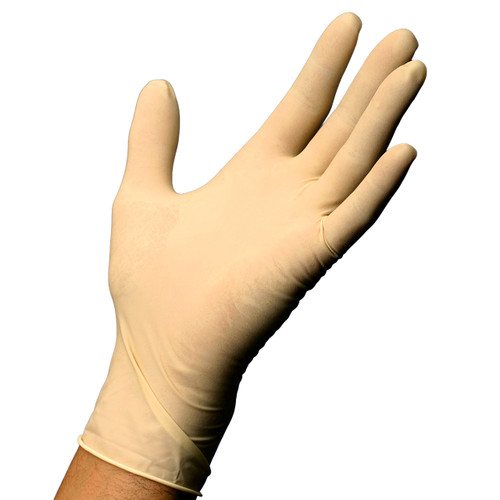

Cleanroom TN300W Series 9.5 Nitrile Gloves — what thin-gauge gloves are designed to control

Cleanroom TN300W Series 9.5 nitrile gloves are designed for cleanroom workflows where

tactile sensitivity and fine motor control are prioritized.

Reduced glove thickness can improve dexterity during assembly, inspection, and precision handling,

particularly when operators must feel edges, alignment features, or surface changes.

Thin nitrile gloves change the risk profile of the glove program.

While they improve tactile feedback, they also reduce the margin for misuse.

Extended wear, solvent exposure, and aggressive handling can compromise integrity faster than with heavier-gauge gloves.

For this reason, thin-gauge gloves perform best when paired with disciplined donning, defined change rules,

and task-appropriate use boundaries.

Operations takeaway: Thin gloves improve precision—but only when the method is controlled.

Reduced thickness requires increased discipline.

ISO-first context: glove thickness changes the failure modes

ISO 14644 operations guidance focuses on personnel as a dominant contamination source.

Gloves are the most frequent contact interface between personnel and controlled surfaces.

When thinner gloves are used, the system becomes more sensitive to technique drift:

excessive pressure, overhandling, and delayed glove changes have a greater impact.

In ISO 5 and ISO 6 environments, thin gloves are often selected for precision work,

but they should be restricted from tasks involving aggressive cleaning, sharp edges,

prolonged solvent exposure, or high abrasion unless the program explicitly supports it.

Technical reference chart (confirm exact values via product page + manufacturer documentation)

| Product family |

Cleanroom TN300W Series |

| Material |

Nitrile |

| Thickness class |

Thin-gauge (9.5 mil class – refer to product page for exact values) |

| Target environment |

ISO 5 / ISO 6 (per product positioning) |

| Sterility |

Refer to product page and packaging |

Selection note: Thin gloves should be specified by task type, not used as a universal glove across all cleanroom activities.

Best-practice use (thin-gauge glove discipline)

Best practice begins with correct task assignment. Thin nitrile gloves should be used for

precision handling, inspection, and light assembly where tactile feedback is critical.

Avoid using thin gloves for abrasive cleaning, heavy wiping, or prolonged solvent exposure

unless validated by the process.

Don gloves using controlled technique and correct sizing.

Thin gloves amplify fit issues—oversized gloves increase friction and snag risk,

while undersized gloves increase stress and tear probability.

Once donned, keep hands within the defined work zone and minimize unnecessary contact.

Define aggressive change rules.

Thin gloves should be changed more frequently than heavier gloves:

after any non-controlled surface contact, after solvent use,

after defined time intervals, or at the first sign of tackiness, thinning, or loss of integrity.

Typical failures with thin gloves—and how to avoid them

- Premature tearing: Using thin gloves for abrasive or high-force tasks. Prevention: task-based glove selection.

- Residue transfer: Extended wear during solvent work. Prevention: shorter change intervals.

- Technique drift: Overconfidence due to “better feel.” Prevention: reinforce light-touch handling.

- Unapproved substitution: Thin glove replacing standard glove across all tasks. Prevention: SOP-defined use boundaries.

- Inconsistent results across shifts: Different wear times and pressures. Prevention: written change and handling rules.

Suggested companion products and technical rationale

Thin-glove programs benefit from tools that reduce direct hand contact

and minimize re-handling during cleaning and inspection.

Disclaimer

This Technical Vault content is provided as supplemental operational guidance only and does not replace

manufacturer instructions, facility SOPs, validation protocols, or regulatory requirements.

Always follow applicable ISO standards and site-specific procedures.

Refer to current manufacturer documentation for performance, sterility, and chemical compatibility.

Control substitutions and document receiving/lot traceability where required.

Questions? Email Sales@SOSsupply.com or call (214) 340-8574.

© 2026 SOSCleanroom. All rights reserved.