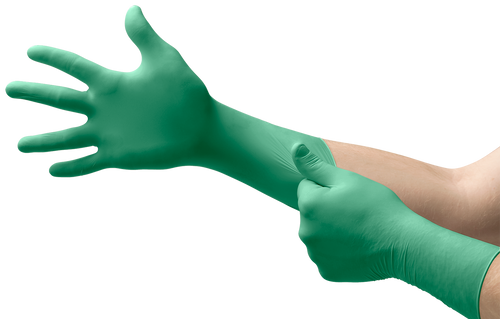

Ansell DERMASHIELD™ 73-711 Sterile Neoprene Cleanroom Gloves — Class 100 / ISO 5 Low-Allergy Protection with Textured Fingertips for Aseptic Handling

Class 100 / ISO 5 EU GMP Grade A Sterile (gamma irradiated) Neoprene (polychloroprene) Latex-free Accelerator-free Textured fingertips DERMASHIELD™ polymer coating Double-gloving friendly Chemo-tested (ASTM D6978) 12" length 200 pairs / case

Product overview

Ansell DERMASHIELD™ 73-711 is a sterile, disposable neoprene cleanroom glove built for aseptic and Class 100 / ISO 5 (EU GMP Grade A) environments where operators want a latex-free, accelerator-free barrier without giving up durability, dexterity or grip. Textured fingertips support controlled handling of components, containers and sterile packaging, while the DERMASHIELD™ internal polymer coating supports donning consistency for long shifts and double-glove programs.

Aseptic handling note

In ISO 5 work, gloves are commonly treated as the highest-frequency product-contact risk. Build glove selection into your contamination-control strategy: consistent sizing, defined change frequency, controlled donning/doffing steps, and clear “touch rules” at critical points of use.

Why customers choose DERMASHIELD™ 73-711

- Designed for aseptic and Class 100 / ISO 5 operations where glove cleanliness, sterility and repeatable technique directly impact yield and batch integrity.

- Latex-free and accelerator-free formulation to help reduce Type I (latex) and Type IV (chemical) sensitivity concerns in long-wear sterile programs.

- Robust neoprene (polychloroprene) film supports puncture resistance and chemical splash protection commonly needed during cleaning and transfers.

- Textured fingertips support secure grip during precise manipulations, especially when handling lightly wetted items or sterile pouch material.

- Double-gloving friendly as an outer glove or underglove (define your program standard so operators do not improvise at the bench).

- Tested for use with chemotherapy drugs in accordance with ASTM D6978 (not listed in the U.S. FDA 510(k) as published).

Recommended applications

- Transferring liquids in controlled environments

- Cleanroom cleaning and preparing (sterile boundary controlled steps)

- Sample taking and processing in aseptic workflows

- Material transfers and staging where glove integrity and documented touch discipline reduce intervention risk

- Programs supporting hazardous drug handling where chemo-tested gloves are specified by policy (always validate to your SOP and risk assessment)

Practical technique tip: define glove-change triggers after contact with carts, door hardware, keyboards, phones, and any surface outside the controlled boundary. In ISO 5 work, “small touches” become the most common source of contamination events.

Specifications (from published technical data)

| SKU |

73-711 |

| Cleanroom classification |

Class 100 / ISO 5 & EU GMP Grade A |

| Sterility / sterilization method |

Sterile; GAMMA irradiation (25 kGy) |

| Material / color |

Neoprene (polychloroprene) / Green |

| Shape |

Anatomic with curved fingers |

| Cuff |

Beaded with SUREFIT™ Technology (standard cuff length) |

| Surface / grip |

Textured fingertip |

| Internal surface |

Polymer coated with DERMASHIELD™ Technology |

| Powder content |

Powder-free |

| Typical glove length |

300 mm / 12 in |

| Freedom from holes (AQL) |

0.65 AQL |

| Typical particle count (cleanroom metric) |

≥0.5 µm: < 3,500 counts / cm² |

| Thickness targets (single wall) |

Palm: 0.18 mm / 7.08 mil

Finger: 0.20 mm / 7.87 mil

Cuff: 0.15 mm / 5.90 mil |

| Double gloving recommendation |

Yes, as outer glove or underglove |

| Tested for use with chemotherapy drugs |

Yes, in accordance with ASTM D6978 (not listed in the U.S. FDA 510(k) as published) |

| Protein level |

N/A: contains no natural rubber latex |

| Anti-static |

No |

| Available sizes |

6, 6.5, 7, 7.5, 8, 8.5, 9 |

| Reorder numbers (by size) |

73711060, 73711065, 73711070, 73711075, 73711080, 73711085, 73711090 |

| Packaging (case) |

200 pairs / case

1 pair per inner poly pack; 10 inner poly packs per inner polybag; 5 outer polybags per bag; 4 bags per master bag; 1 master bag of 200 pairs per carton/case |

| Shelf life |

5 years |

| Storage guidance |

Keep out of direct sunlight; store in a cool, dry place; keep away from ozone or ignition sources. |

| Country of origin |

Sri Lanka |

| Quality / regulatory notes (as published) |

Audit standard: ISO 9001:2015

Regulatory references include: AS/NZS 4179, ASTM D3577, ASTM D7160, CE 0493, EN 556-1:2001, EN ISO 21420:2020, EN ISO 374-1:2016, EN ISO 374-5:2016, EN 421:2010, ISO 10282, ISO 11193, ISO 13485 |

Test method context (as published): particle metric references IEST-RP-CC005.4; thickness/length references EN 420 / ASTM D3767; AQL references EN 455-1 / ASTM D3577; chemo permeation references ASTM D6978. Always validate glove selection in your process, including disinfectant compatibility, product-contact risk, and operator technique.

Cleanroom program guidance (U.S. first, global context second)

In U.S.-based cleanrooms and regulated operations, gloves are typically treated as a primary contamination-control and mix-up risk at point of use. Many programs use ISO 14644 terminology to align cleanroom classification language, while sterile processing expectations are managed through internal quality systems and risk-based controls aligned to FDA expectations for documented training, investigations and change control. If your operation includes hazardous drug handling, ensure glove selection, double-glove rules, and change frequency are defined by policy and validated to your specific workflow (USP <800> is commonly used as a U.S. framework in applicable settings).

As a secondary/global benchmark, EU GMP Annex 1 reinforces contamination control strategy (CCS) discipline: controlled material transfers, defined glove-change triggers at critical steps, and documentation that supports traceability and investigation readiness. Use Annex 1 as a continuous improvement lens where it fits your business, without treating it as a U.S. legal requirement.

Helpful standards and guidance hubs (for program reference): https://www.iso.org/standard/53394.html | https://www.fda.gov | https://www.astm.org | https://www.iest.org

Build a best-in-class ISO 5 consumables set

SOSCleanroom does not compromise on glove quality in critical environments. Ansell is positioned as a best-in-class glove line for customers who need consistent controlled-environment performance and documentation discipline. To reduce overall contamination risk in ISO 5 operations, pair sterile gloves with ISO 5-aligned wiping and swabbing materials that support controlled wetting, residue control, and repeatable technique.

Texwipe pairing suggestions (ISO 5-aligned wiping and swabbing)

For over 35 years, SOS and Texwipe have been close partners, and SOSCleanroom is the authorized Master Distributor of ITW Texwipe for the United States market. For ISO 5 cleaning and wipe-downs, many customers standardize on sterile 100% polyester wipers and sterile cleanroom swabs for corners, ports, threads, and detail cleaning. Where a low-linting wiper is required, remember that no wiper is truly lint-free under all process conditions.

- Sterile wiping: Texwipe sterile AlphaWipe® polyester wipers for controlled application of disinfectants and cleaning solutions in ISO 5 workflows.

Learn more: https://www.texwipe.com/sterile-alphawipe

- Sterile swabbing: Texwipe CleanTips® sterile Alpha® polyester knit swabs for precision cleaning and residue removal in tight geometries (thermal bond construction to eliminate adhesive contamination; trademarked green handles and embossed Texwipe branding support authenticity and lot-level traceability at point of use).

Learn more: https://www.texwipe.com/alpha-polyester-knit-cleanroom-swabs-sterile

- General ISO 5 cleaning (non-sterile support areas where appropriate): Texwipe AlphaWipe® TX1009/TX1009B low-linting polyester wipers are commonly used for controlled cleaning and spill control in ISO-classified spaces (verify suitability to your area classification and SOP).

Learn more: https://www.texwipe.com/alphawipe-tx1009

About Ansell and SOSCleanroom supply confidence

Ansell is a global manufacturer of hand and body protection solutions with controlled-environment product lines used across life sciences, critical manufacturing and laboratory settings. In cleanrooms, consistency matters: formulation control, packaging discipline and the ability to support documentation requests when customers qualify and sustain a glove program.

SOSCleanroom supports customers who need dependable, best-in-class cleanroom consumables with fast shipping, excellent customer service, fair pricing, and continuity of supply backed by decades serving controlled environments. Third-party validation: Cleanroom Technology reported that SOS Cleanroom Supply became an Ansell authorised distributor (June 20, 2023): https://cleanroomtechnology.com/sos-cleanroom-supply-becomes-ansell-authorised-distributor-209576

If you have any questions please email us at Sales@SOSsupply.com or give us a call at (214)340-8574.

If you need additional information please try our SOSCleanroom specific AI ChatBot which draws from our extensive cleanroom specific libraries.

Last updated: January 10, 2026

© 2026 SOSCleanroom.com