Ansell

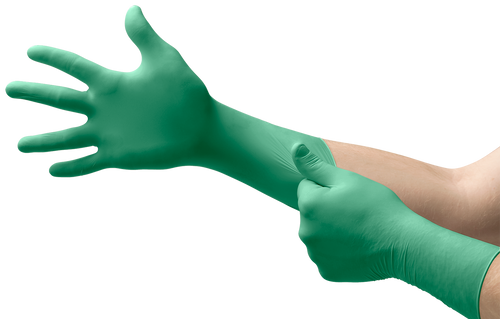

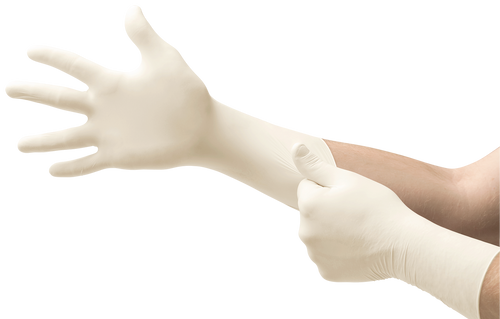

Ansell 83-500 TouchNTuff Sterile Polyisoprene Gloves Class 100 (ISO 5)

$565.70

- SKU:

- 83-500

- Availability:

- 7 - 10 Business Days

- Shipping:

- Calculated at Checkout

- Quantity Option (Case):

- 200 Pairs

- Inner Packaging:

- See Below