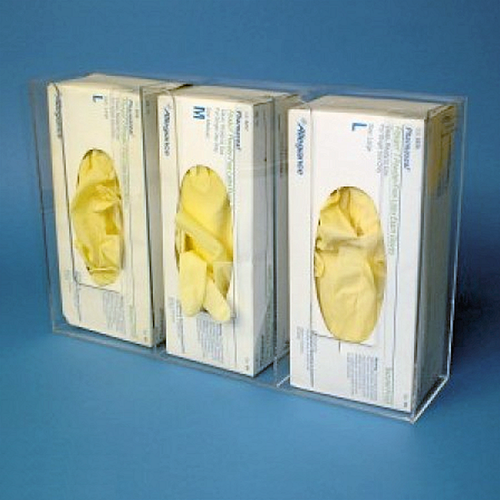

Cleanroom Exam Glove 1-Box Dispenser (Holds Boxes Vertically) — Clear Acrylic, Wall-Mount

This vertical single-box glove dispenser is a simple, high-impact control for gowning rooms, airlocks, and point-of-use stations: it keeps the glove box off benches, standardizes how operators access gloves, and reduces incidental contact with external packaging during routine changeovers.

In critical environments, “organization” is not cosmetic — it is contamination control. A dedicated dispenser creates a repeatable touch-point (same access location, same pull angle, same restock method), which helps teams follow SOPs more consistently and reduces the chance that glove packaging becomes a source of particles, fibers, or cross-contact.

Published configuration (1-box vertical model)

- Material: Clear acrylic (available only in clear acrylic)

- Construction thickness: 1/8" clear acrylic

- Capacity: Holds 1 box of exam gloves (vertical orientation)

- Mounting: Wall-mount; screws and wall anchors provided

- Overall size: 5.5"W x 11"H x 4"D

- Case pack: 5 dispensers per case

Why dispensers matter in cleanrooms

The highest-risk moments for gloves are not just “during work” — they are during changeovers: opening cartons, moving boxes, handling torn cardboard edges, and grabbing gloves with inconsistent technique. A dispenser helps by (1) enclosing and stabilizing the box, (2) controlling the access point, and (3) keeping glove inventory visible and orderly so teams don’t overstock benches “just in case.”

Recommended gloves and nearby consumables (with internal links)

This dispenser is sized for a single exam-glove box. The glove you choose should match your process requirements (non-sterile vs sterile, chemical exposure, dexterity needs, and defect targets). Below are commonly specified options customers stage at the point of use:

- Kimtech Purple Nitrile-Xtra Exam Gloves (12"): View product A dependable nitrile exam glove option when teams want additional cuff length coverage and consistent dispensing workflow.

- Kimtech Polaris Nitrile Exam Gloves: View product A premium exam-glove program option for high-discipline lab/production workflows where grip and documented testing matter.

- Ansell MICROFLEX® XCEED® XC-310 Nitrile Exam Gloves: View product A high-throughput dispenser format glove option for repetitive tasks where tactile response and hand comfort are key decision drivers.

- Texwipe TX1009 AlphaWipe® 9" x 9" Polyester Cleanroom Wiper: View product Stage a cleanroom wiper adjacent to the dispenser to support controlled wipe-down of the wall area, dispenser exterior (per SOP), and restock handling zones.

- Kimtech PURE A5 Sterile Cleanroom Hoods (if your program requires sterile gowning components): View product For ISO 5 / aseptic gowning programs, stage appropriate sterile apparel outside the core to support disciplined donning and reduce “searching” behavior inside controlled areas.

Practical use guidance (what good looks like)

- Place it where decisions happen: mount at the glove-change point (gowning room, airlock entry, or tool cell), not “somewhere convenient.”

- One box, one purpose: avoid mixing glove types at the same station unless your SOP clearly labels use-cases (e.g., sampling vs cleaning vs chemical handling).

- Restock discipline: restock with clean hands/gloves; do not slide damaged cardboard into the dispenser — replace it.

- Changeover control: when switching glove lots, remove the old box fully, wipe the dispenser exterior per your SOP, then install the new lot to prevent mixed-lot ambiguity.

- Labeling: consider a small wall label adjacent to the dispenser with glove type, size, and approved use (reduces errors and unnecessary waste).

Material + cleaning compatibility (critical detail)

This model is clear acrylic. Acrylic is valued for a clean appearance and scratch resistance, but cleaning chemistry matters.

- Routine cleaning: if your SOP permits, use soap and water on acrylic dispensers and dry fully before service.

- Avoid harsh solvent wipe-downs on acrylic: repeated IPA exposure can drive cracking/deterioration over time.

- If your facility requires IPA wipe-down: many programs standardize PETG dispensers for chemical compatibility. If that is your situation, contact SOSCleanroom and we will help you select a dispenser material aligned to your cleaning agents and qualification expectations.

Where dispensers reduce waste (without sacrificing control)

Dispensers help teams avoid “bench piles” of consumables that get over-handled, crushed, or prematurely discarded. By keeping one active box in a defined location, you reduce unnecessary glove changes driven by confusion (wrong glove at the station), damage (torn cartons), and overstock habits that expire or get contaminated before use.

Browse related dispenser solutions

If you have any questions please email us at Sales@SOSsupply.com or give us a call at (214)340-8574.

Check out the AI ChatBot powered by SOSCleanroom data libraries - give it a try!

THIS IS NEW FOR 2026!

© 2026 SOS Supply. All rights reserved.