The Technical Vault

By SOSCleanroom

Station Control Component

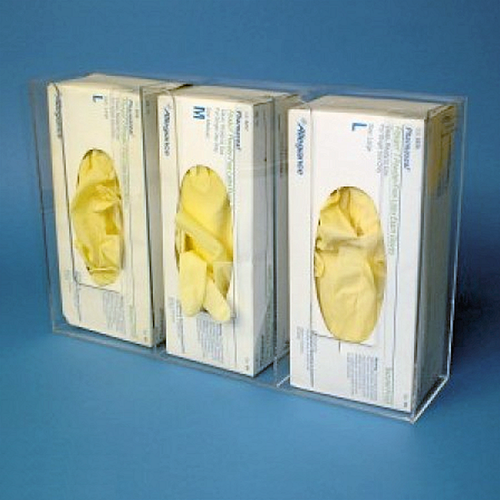

Glove Box Dispenser (2-Box Vertical)

Acrylic (1/8")

11"W x 11"H x 4"D

Holds 2 Boxes (Vertical)

Soap + Water Cleaning (Acrylic)

Cleanroom Exam Glove 2-Box Dispenser (EBD-2UP, Acrylic) — why it improves glove-change outcomes

In critical environments, “glove storage” is not a convenience detail. It is a contamination-control control point. When glove cartons are placed on open shelving, benches, or carts, they pick up residues and become a frequent-touch surface. A dedicated dispenser creates a defined, repeatable glove-change station that reduces touch variability, supports visual inventory control, and helps teams avoid waste driven by lost partial boxes.

1) What this dispenser is (and what it is not)

- It is: a wall-mounted, clear acrylic holder designed to stage two glove boxes vertically for controlled dispensing and visibility.

- It is not: a sterilizing device, a sealed enclosure, or a replacement for validated glove program controls (qualification, change control, and SOP-driven glove-change frequency).

- Important boundary: glove “cleanroom suitability” is determined by the glove, its packaging, and how it is transferred into the space—not by the dispenser alone.

2) Published specifications (manufacturer listing)

| Attribute |

Published value |

Why it matters |

| Material |

Clear acrylic, 1/8" |

Rigid, highly visible, and scratch-resistant compared to PETG (per published comparison). |

| Capacity |

2 glove boxes (vertical) |

Allows two sizes or two glove types at one station. |

| Overall size |

11"W x 11"H x 4"D |

Compact footprint; supports point-of-use placement without creating an obstruction. |

| Mounting |

Screws + wall anchors provided |

Reduces improvised mounting that leads to vibration, cracking, or accidental drops. |

| Case pack |

5 per case |

Supports standardizing multiple stations (gowning, pass-through, line entry). |

3) Why acrylic is chosen (and when it is the wrong choice)

Acrylic is selected for cleanroom dispensers because it is clear, rigid, and (per the manufacturer comparison) more scratch-resistant and lower cost than PETG. The tradeoff is chemical compatibility: the published guidance states acrylic is ideal when the environment does not require IPA or harsh chemical wipe-down, and it should be cleaned using soap and water.

If your facility uses IPA on dispensers

The published comparison notes PETG is preferred for compatibility with IPA and harsh chemicals, and that using IPA on acrylic can cause deterioration/cracking over time. Treat this as a materials-compatibility decision: align to your cleaning agent list, contact time, and frequency in your SOP before standardizing.

4) Donning discipline: ISO first, then Annex 1 (practical station behaviors)

ISO-aligned behaviors (operations discipline): treat the dispenser face and glove box opening as a controlled touch point. Use a consistent “one glove at a time” withdrawal motion; avoid dragging sleeves or garment cuffs across the box opening; and replace crushed cartons (paper dust and deformation are common dispensing failure modes).

EU GMP Annex 1 mindset (aseptic programs): if gloves are used in or near aseptic processing, the dispenser location should be part of the broader contamination control strategy (CCS): validated transfer practices, defined glove-change cadence, and sanitization steps as required by your SOP. The dispenser supports consistency; it does not substitute for aseptic technique validation.

5) Matching consumables (why “pairing” matters)

Exam glove options (box-dispense workflows)

-

Kimtech™ Polaris™ — published AQL 0.65 and thicker “work glove” positioning for demanding lab and controlled support tasks.

-

Ansell XC-310 — thin-mil, ergonomic exam glove format commonly used in high-touch work where dexterity matters; qualify per SOP for cleanroom entry.

Wiper support (keeping the station from becoming a residue collector)

-

Texwipe TX1009 AlphaWipe — a standard polyester knit wiper used across ISO Class 4–8 controlled areas for routine wipe-down support (align chemistry to your surface list and SOP).

Garment interface (reducing sleeve/glove failure points)

SOSCleanroom note on accuracy and qualification

Dispensers improve consistency, but your quality system determines suitability. Confirm glove class/processing, packaging transfer method, and cleaning chemistry compatibility before release to production. When you need manufacturer documentation, stable product lineage, and help standardizing stations across multiple rooms, SOSCleanroom supports that program-level work.

© 2026 SOSCleanroom. All rights reserved.