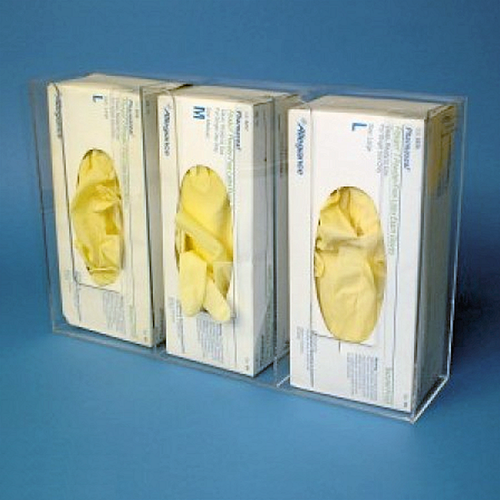

Cleanroom Exam Glove 3-Box Dispenser (Holds Boxes Horizontally) — Clear Acrylic, Wall-Mount

This 3-box horizontal dispenser is built for clean, repeatable glove access in gowning rooms, controlled corridors, and point-of-use workcells. By holding glove cartons in a fixed, visible location, it reduces bench clutter, lowers unnecessary touches on outer packaging, and helps operators select the correct glove type/size without “search behavior” that drives contamination risk and avoidable waste.

The housing is clear acrylic for visibility and visual inventory control. If your facility uses IPA wipe-down on dispensers and fixtures, review the material note below and align to your SOP before standardizing.

Published configuration (EBD-3000, Acrylic)

- SKU: EBD-3000 (Acrylic)

- Availability: Made to Order, 14–21 business days

- Material: Available only in clear acrylic

- Thickness: 1/8" clear, clean acrylic (easy to read through)

- Mounting: Fastens securely to wall (screws and wall anchors provided)

- Capacity: Holds 3 boxes of gloves

- Case unit: 1 dispenser per case

- Size: 10.25"W x 15"H x 3.5"D

What you receive

This listing is for the dispenser only. Gloves, bouffants, wipers, and apparel shown in any images are not included.

Why dispensers help cleanliness (and reduce waste)

- Touch reduction: A fixed glove station reduces repeated handling of cartons that often become high-touch surfaces in gowning areas.

- Fewer “wrong glove” events: Three dedicated slots make it practical to separate sizes or define use-based gloves (sampling vs general handling vs cleaning support).

- Less carton damage: Dispensers stabilize boxes and reduce crushing/tearing, which commonly causes double-pulls and glove disposal.

- Inventory visibility: Clear acrylic supports quick checks so teams restock proactively instead of staging extra boxes on benches.

Material construction and cleaning compatibility (acrylic vs PETG)

This model is acrylic. Acrylic is commonly selected for dispensers because it is clear, rigid, and scratch-resistant. The cleaning chemistry matters:

Cleaning checkpoint (align to your SOP)

Published guidance states acrylic is ideal where dispensers are not routinely cleaned with IPA or harsh chemicals; for acrylic, cleaning is described as soap and water. PETG is described as the preferred material when IPA/harsh chemical compatibility is required, because repeated IPA exposure on acrylic can lead to deterioration and cracking over time.

Recommended station pairings (with internal product links)

Gloves (choose sizes or define by task)

- Kimtech Purple Nitrile-Xtra Exam Gloves A strong boxed exam-glove option for high-use stations. Confirm sizing, thickness, and compliance needs on the product page before standardizing.

- Kimtech Polaris Nitrile Exam Gloves Often selected when teams want a premium exam-glove line for controlled workflows. Review the product page for published testing and packaging details.

- Ansell MICROFLEX® XCEED® XC-310 A high-throughput nitrile exam glove option commonly used at point-of-use stations. Qualify for your environment per SOP.

Wipers (keep the station clean without adding debris)

- Texwipe® TX1009 AlphaWipe® 9" x 9" Stage a qualified cleanroom wiper adjacent to the dispenser to support controlled wipe-down of nearby wall surfaces and cleaner restocking practices (per your chemistry/SOP).

Garments (reduce movement and improve gowning consistency)

- Kimtech PURE A5 Sterile Cleanroom Hoods When sterile gowning components are required, staging them with glove access reduces “searching” behavior and prevents unnecessary traffic in controlled zones.

Setup guidance (simple controls that hold up in audits)

- Label each slot: glove type/size and approved use (reduces wrong-glove pulls and trial-pulls).

- Restock discipline: define when to replace (before cartons deform) and how to manage lot changes (avoid mixed lots without control).

- Keep out of splash zones: wet cartons deform and dispense poorly, creating glove waste and touch errors.

- Clean + dry time: clean the dispenser exterior per SOP and allow full dry time before restocking/handling.

Why source through SOSCleanroom?

Customers standardize dispensers to improve repeatability across rooms and shifts. SOSCleanroom supports station-level standardization by pairing dispensers with proven product families (Texwipe, Ansell, Kimtech) and helping teams maintain continuity of supply and documentation discipline over time.

If you have any questions please email us at Sales@SOSsupply.com or give us a call at (214)340-8574.

Check out the AI ChatBot powered by SOSCleanroom data libraries - give it a try!

THIS IS NEW FOR 2026!

© 2026 SOS Supply. All rights reserved.