The Technical Vault

By SOSCleanroom

Dispensers • Glove Control • Gowning Stations

Last reviewed: Jan. 21, 2026

How a 3-Box Glove Dispenser Improves Cleanroom Discipline (and Reduces Waste)

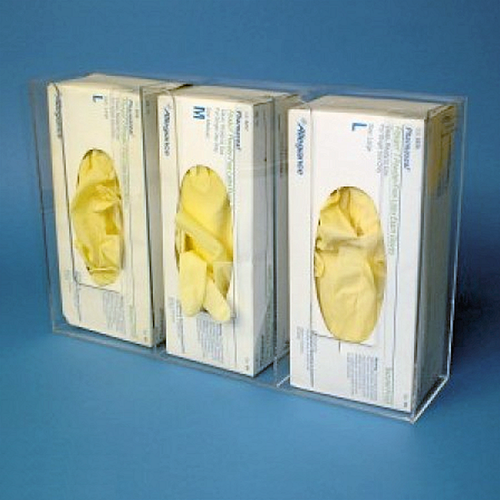

The Cleanroom Exam Glove 3-Box Dispenser is a simple control that supports reliable glove availability, cleaner staging, and fewer avoidable consumable losses. It is built from 1/8" clear acrylic, mounts to the wall, and holds three boxed glove dispensers in a vertical orientation. :contentReference[oaicite:12]{index=12}

1) The operational problem this dispenser solves

- Box migration: loose glove cartons get moved between rooms, stacked on carts, and set on benches—raising contact exposure and crushing boxes (leading to glove waste and inconsistent dispensing).

- Over-handling: when operators hunt for sizes, they “test pull,” touch multiple cartons, or open secondary boxes—creating avoidable waste and handling risk.

- Inventory blind spots: if stock is not visible, teams substitute glove types mid-process—creating variability that can trigger deviations or requalification conversations.

Cleanliness benefit in plain language

A dispenser cannot “make gloves cleaner,” but it can reduce the number of ways your glove cartons get touched, bumped, splashed, crushed, and relocated. Fewer interactions generally means fewer opportunities for unnecessary contamination transfer and fewer gloves thrown away due to damaged packaging.

2) Material selection: acrylic vs PETG (selection guidance you can defend)

This model is clear acrylic and is published as available only in acrylic. Acrylic is valued for appearance and scratch resistance, and the manufacturer guidance recommends soap and water cleaning. :contentReference[oaicite:13]{index=13}

The same manufacturer guidance explains that PETG is often selected when facilities routinely wipe dispensers with IPA or harsh disinfectants, because repeated IPA exposure can cause acrylic to deteriorate/crack over time. If IPA wipe-down is mandatory in your SOP for high-touch fixtures, that chemistry requirement should drive your dispenser material standard. :contentReference[oaicite:14]{index=14}

3) Standardization: what to stage in a 3-box format

A 3-box vertical dispenser is most effective when it is treated as a program control (not “storage”). Common staging patterns:

- Sizes (most common): S / M / L for shared stations to reduce “wrong size” pulls and time loss.

- Task-based: general handling nitrile / chemical-handling nitrile / high-dexterity nitrile (only if your SOP clearly defines where each is used).

- Area-based: warehouse staging vs controlled support vs gowning entry—avoid mixing categories if it encourages “same gloves everywhere” behavior.

Selection reminder (accuracy matters)

Box dispensers are typically used with non-sterile exam gloves. If your operation requires sterile cleanroom gloves or cleanroom-processed packaging flows, validate packaging format and material flow before standardizing wall dispensers for that area.

4) Pairings that work well with this dispenser (linked)

Boxed exam gloves that stage cleanly

Wipers to manage the “high-touch zone” around glove stations

-

Texwipe TX1009 AlphaWipe

— published as polyester, 9" x 9", used across ISO 4–8 environments (as listed), and constructed from continuous-filament polyester in a knit pattern for durability. :contentReference[oaicite:17]{index=17}

Garments that complement glove discipline in gowning / entry sequences

-

Kimtech Pure A5 Sterile Cleanroom Hoods

— staged at entry points to complete head coverage before glove donning and surface contact. :contentReference[oaicite:18]{index=18}

-

Kimtech A8 Lab Coat (example)

— SMS fabric platform commonly used for controlled areas; size your program and staging to reduce garment handling and re-donning events. :contentReference[oaicite:19]{index=19}

5) Cleaning, inspection, and lifecycle controls

- Define a cleaning method that matches the material: acrylic is published for soap-and-water cleaning; avoid assuming IPA compatibility for acrylic. :contentReference[oaicite:20]{index=20}

- Inspect mounting points: dispensers are frequently “leaned on” during hurried donning. Add a quick weekly check for loosened fasteners.

- Control scuffs and cracking: replace dispensers that develop cracks, sharp edges, or persistent haze that prevents visual inventory checks.

- Program control: label each slot (Size / Glove Type / Area) to prevent substitution and reduce waste from wrong-glove pulls.

Why many teams standardize through SOSCleanroom

Cleanroom consumables are only “clean” if the program is consistent—product lineage, documentation access, and repeatable packaging formats matter. SOSCleanroom supports standardization with deep category coverage (Texwipe, Ansell, Kimtech), responsive technical help, and supply continuity planning for critical environments.

© 2026 SOS Supply. All rights reserved.