S-CURVE

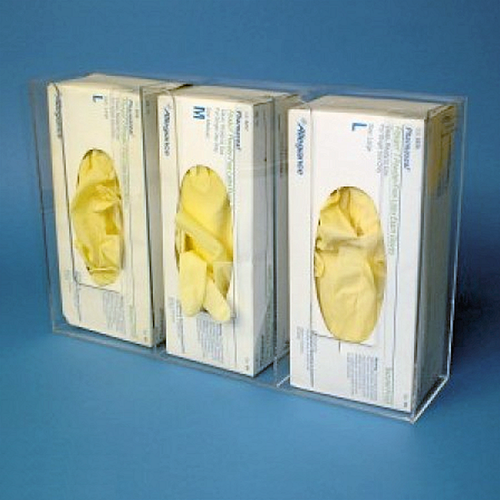

Cleanroom Exam Glove 4-Box Dispenser (Holds Boxes Vertically)

$121.43

- SKU:

- EBD-4UP (Acrylic)

- Availability:

- Made to Order, 14 - 21 Business Days

- Shipping:

- $25.00 (Fixed Shipping Cost)

- Quantity Option (Each):

- 1 Dispenser