CCI

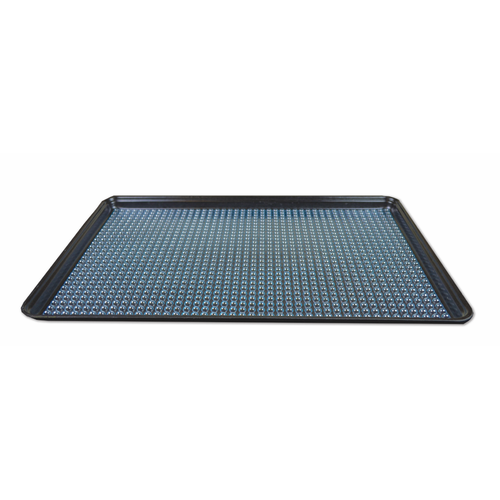

KSB2416-MB-40-TPU Kleanstat Flex (KSF) TPU ESD Medium Airless Bubble Tray Liner 24.25" x 16.125" x .375" (.040 Gauge)

$550.00

- SKU:

- KSB2416-MB-40-TPU

- Availability:

- 10 - 14 Business Days

- Shipping:

- Calculated at Checkout

- Quantity Option (Case):

- 10 Tray Liners