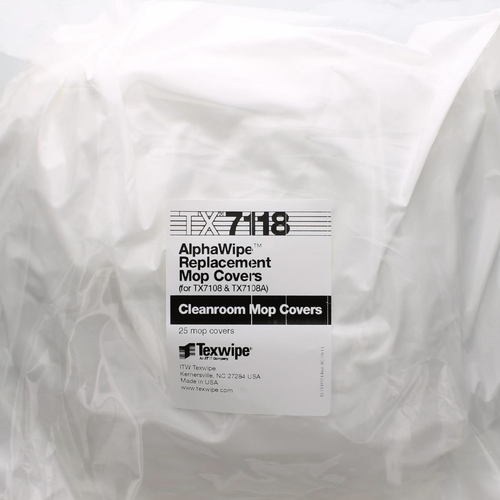

ITW TEXWIPE

Texwipe TX7108 AlphaMop Polyester Cleanroom Mop with Fiberglass Handle

$110.33

- SKU:

- TX7108

- Availability:

- Stock Item

- Shipping:

- Calculated at Checkout

- Type:

- Dry Mop

- Quantity Option (Each):

- 1 Mop