Osram / Sylvania

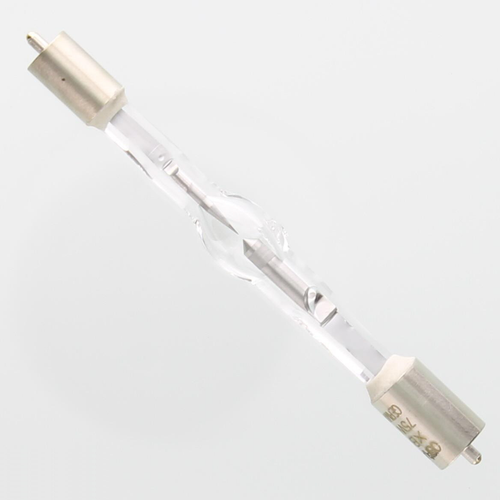

Osram Sylvania G25T8 25W 18" UV Germicidal Lamp

$7.10

- SKU:

- G25T8 (55197) EACH

- UPC:

- 4008321398857

- Availability:

- Stock Item

- Shipping:

- Calculated at Checkout