How a Short-Arc Mercury Lamp Works (Engineering Detail)

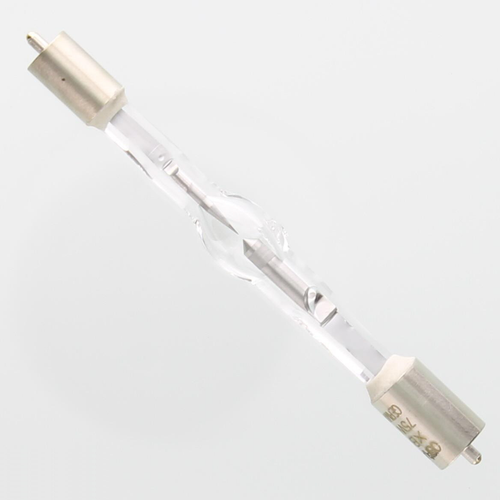

An HBO lamp is a gas-discharge light source: instead of a filament, it produces light from an electric arc burning between two

robust electrodes inside a quartz (fused silica) burner. The arc gap is intentionally very short (“short-arc”), concentrating power into a tiny

volume of plasma. That is the design reason these lamps behave like an intense near-point source—ideal for optical systems that must efficiently

collect and focus light (microscopes, fiber illumination, UV-enabled instruments).

Start-up and run-up: When cold, mercury is present as small metallic droplets. A high-voltage ignition pulse initiates a discharge in the starting gas,

and the arc rapidly heats the burner. As temperature rises, mercury vaporizes, internal pressure increases, and the lamp transitions to a stable high-pressure arc.

The electrical behavior changes during this warm-up period, which is why the lamp requires the correct ballast/driver and igniter matched to the lamp type and power.

Why the spectrum looks “spiky”: Mercury plasmas emit strong spectral lines in the UV and visible. In microscopy and analytical optics, filters and dichroics are commonly chosen

around prominent mercury lines (for example, wavelengths commonly referenced include ~365, 405, 436, 546, and ~578–579 nm), which is one reason mercury arcs remain widely used for fluorescence illumination.

AC operation and orientation: This model is specified for AC operation. AC lamps alternate electrode roles every half-cycle, and stable arc behavior depends on correct power supply design

and correct installation orientation. OSRAM specifies a s45 burning position and to observe the “UP” marking—this is not cosmetic; it supports thermal balance, arc stability, and predictable electrode wear patterns.

Industry Update: ENI Business Transition (Closing Expected End of March 2026)

ams OSRAM announced an agreement (July 2025) to sell its Entertainment & Industry Lamps (ENI) business to Ushio,

with closing expected by the end of March 2026.

Buyer best practice: keep the manufacturer ordering code (69213) in your maintenance records and qualify alternatives by

electrical requirements (50W / 39V nominal; AC; current range), base (SFa6-2), LCL (22mm), and burning position (s45 / “UP”).