Quick Specs

| Manufacturer / Ordering Code |

Osram / Sylvania HBO50W/AC L2 (69214) |

| Lamp Technology |

High-pressure mercury short-arc discharge (near point source) |

| Nominal Electrical |

50W, 34V nominal, 1.3–1.5A, AC (lamp voltage 34–39V) |

| Photometric (Nominal) |

2000 lm, 230 cd, 40 lm/W |

| Base / Connection |

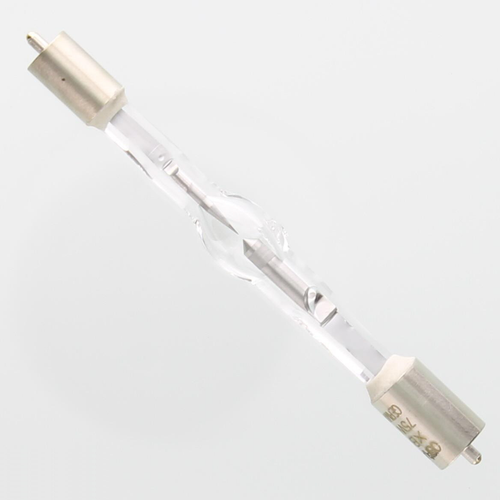

SFa6-2 (both ends) |

| Critical Geometry |

Length 53mm; Diameter 10mm; LCL 22mm |

| Nominal Lifetime |

100 hours |

| UPC/EAN |

4050300507118 |

How a Mercury Short-Arc Lamp Works (Engineering Overview)

A short-arc mercury lamp is a gas-discharge plasma light source. Inside a high-quality quartz discharge vessel, two electrodes are separated by a small gap. At start-up, the power supply applies an ignition sequence and then regulates current through the arc. As the lamp warms, mercury rapidly vaporizes and the internal pressure rises to very high levels, creating a dense, extremely bright arc plasma.

The “short-arc” geometry is the key design advantage: because the light-emitting arc is only a few millimeters long, the lamp approximates a point source. Optical systems can then collect and focus the radiation efficiently through a lamphouse reflector and condenser optics, enabling high irradiance and repeatable alignment in microscopy and precision illumination.

Unlike incandescent sources (continuous spectrum), mercury arcs produce intense radiation in selected wavelength bands. In microscopy and UV processes, the system typically uses filters and dichroics to isolate the desired bands and deliver stable excitation to the target.

Spectrum: Why Mercury Arcs Excel in Microscopy and UV Work

Mercury arc systems are valued because they provide high radiant power in the UV/visible region and can be paired with filter sets to deliver strong excitation at specific bands. Commonly leveraged mercury lines include strong UV/blue bands around 365nm (often called i-line), 405nm (h-line), and 436nm (g-line), along with prominent visible lines such as 546nm and 577/579nm. In fluorescence microscopy, these discrete bands enable efficient excitation of many fluorophores when matched to the correct filter cube.

For UV curing and irradiation, systems often prioritize UVA output (commonly strongest around the 365nm region in standard mercury lamp spectra) and manage dose delivery through optics, shutters, and irradiance monitoring.

Ignition & Ballast Matching (AC Lamp)

- Use the correct supply type: HBO50W/AC L2 is specified for AC operation. Do not substitute a DC-rated supply unless the tool OEM explicitly supports it.

- Current regulation is non-negotiable: Arc lamps require a ballast/power supply that limits and stabilizes current (nominal 1.3–1.5A for this model). Incorrect regulation can cause unstable arc, output drift, or shortened life.

- Observe burning position guidance: HBO lamps can have orientation constraints (the OSRAM listing calls out observing the “UP” marking). This matters for thermal balance and arc stability in the lamphouse.

Compatibility & Cross-Reference Notes

Many tools reference this lamp family by OEM part number rather than the manufacturer ordering code. Keep both your internal maintenance records and purchase specifications anchored to HBO50W/AC L2 and 69214.

Common cross-references may include microscope/lamphouse codes used by major instrument brands. When qualifying, match the electrical rating, base type, and critical geometry (length/LCL)—these directly affect optical alignment and delivered irradiance.

Safety & Handling (High Pressure + UV + Mercury)

HBO lamps produce very high luminance and UV radiation and operate under high internal pressure when hot. They must be operated only in enclosed lamp casings designed for this purpose. If a lamp breaks, mercury can be released—follow the tool OEM’s safety procedure, PPE requirements, and disposal guidance.

Cleanroom Considerations

Treat lamp replacement like controlled maintenance: minimize packaging debris, avoid shedding materials, and prevent residue transfer to adjacent optical surfaces.

For best results, stage clean nitrile gloves and a Texwipe cleanroom-grade lint-free wiper (and, when needed, cleanroom swabs for tight areas) during installation to reduce contamination risk and protect optical performance.

Industry Update (Expected Close by End of March 2026)

ams OSRAM announced an agreement to sell its Entertainment & Industry Lamps (ENI) business to Ushio for €114m, with closing expected by the end of March 2026 and approximately 500 employees transitioning. Practical takeaway: keep your procurement and tool documentation anchored on the manufacturer ordering code (69214), lamp type (AC), and critical geometry to reduce risk during any labeling or channel changes.

Need deeper specs or cross-references?

If you need additional information please try our SOSCleanroom specific AI ChatBot which draws from our extensive cleanroom specific libraries.

For mission-critical microscopy/UV tools, validate OEM requirements for ballast/ignition, lamphouse alignment, cooling, interlocks, and UV shielding before use.