SOS

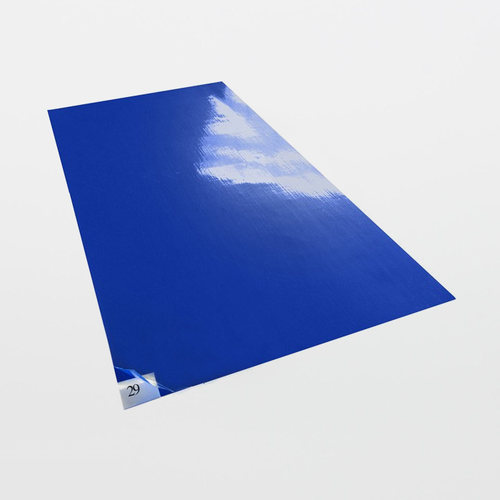

18" x 45" Adhesive Tacky / Sticky Mats (120 Sheets)

$61.25

- SKU:

- CRP0430-2

- Availability:

- Stock Item

- Shipping:

- Calculated at Checkout

- Quantity Option (Case):

- 4 Mats of 30 Sheets (120 Sheets)