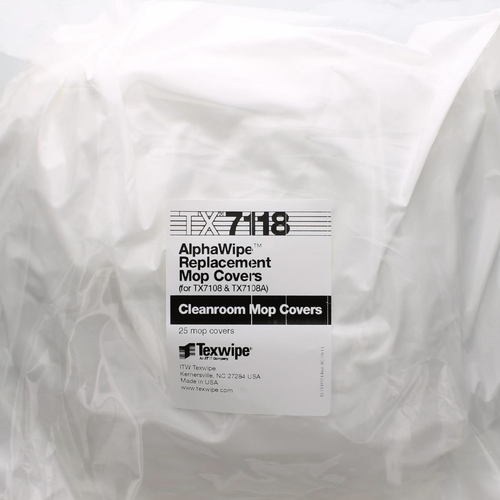

Texwipe TX7118F AlphaMop™ Polyester Pad Replacement Kit — 8" x 15" Pads, Non-Sterile (75 Pads/Case)

TX7118F is a replacement pad kit for the AlphaMop™ flat-mop system, used to keep the mop cover properly cushioned and conforming when cleaning floors, walls, and ceilings in controlled environments. Each kit case includes three inner bags of pads (25 pads per bag) plus fastening pins to secure pads to the AlphaMop head assembly. In practice, these pads help technicians maintain consistent surface contact across textured flooring, coved transitions, wall panels, and hard-to-reach areas where “skipping” or uneven contact can leave residues behind.

For over 35 years, SOS and Texwipe have been close partners, and SOSCleanroom is the authorized Master Distributor of ITW Texwipe for the United States market. That relationship matters for critical-environment cleaning programs because it supports continuity of supply, stable product lineage, and fast access to the manufacturer documentation your QA/QC team expects.

Published configuration (TX7118F)

- Product type: AlphaMop™ pad replacement kit (pads + fastening pins)

- Pad size: 8" x 15" (packed)

- Sterility: Non-sterile

- Inner pack: 25 pads + 4 fastening pins per bag

- Case pack: 3 bags per case (75 pads + 12 fastening pins per case)

- Cleanroom packaging: Double-bagged inner packaging (for easier controlled-environment introduction)

- Compatible systems: For use with AlphaMop™ TX7108 (and AlphaMop™ autoclave-safe head assemblies where specified by the program)

- SOSCleanroom listing notes: Case quantity option published as “75 foam pads and 12 clips/pins per case (3 bags of 25 pads and 4 clips/pins)”

Low particle / low-linting intent — and the reality check

AlphaMop™ components are designed for controlled cleaning with low particle and low-linting behavior compared with conventional floor-care tools. Even so, no mop component is truly “zero particle.” Treat pads and covers as contamination-controlled process items: control staging, bag opening, change frequency, and cross-contamination barriers the same way you would for wipes and swabs.

How TX7118F fits into the AlphaMop™ cleaning system

- Purpose of the pad: The pad provides a cushion layer so the mop cover maintains consistent contact with the surface, which improves removal of residues and helps reduce streaking when applying or removing solutions.

- Change strategy: Pads are typically changed when compression set, tearing, pin loosening, or visible contamination is observed, or when the facility SOP defines a maximum use time/area coverage limit.

- Fastening pins: Fastening pins secure pads to the head assembly. Correct pin placement and verification before entry into the clean area helps prevent pad shift, snagging, and particle generation from abrasion.

- Protocol alignment: AlphaMop™ is designed to support “quick-change” behavior (frequent surface refresh) to reduce cross-contamination risk during critical cleaning.

Practical cleanroom use guidance (technicians and engineers)

- Bag opening discipline: Stage the case outside the controlled area per SOP, then introduce only the needed inner bag(s). Open inner packaging slowly to reduce air disturbance and particle mobilization.

- Pin verification step: After fastening the pad, perform a quick “edge sweep” check (gloved fingertip around the perimeter) to ensure no lifted corners and that pins are fully seated before installing the cover.

- Conformance matters on textured floors: If you see pattern streaking, missed valleys, or “chatter” marks, it is often a pad compression/fit issue (or over-wringing). Replace the pad and confirm cover fit before changing chemistry.

- Cross-contamination control: Treat pads as zone-specific consumables. Do not move pads between rooms/grades. Use color/label controls or dedicated carts if your program uses area segregation.

- Change frequency is a control knob: For critical environments, increasing change frequency is one of the simplest controls to reduce redeposition and bioburden/film carryover when using disinfectants.

Compatibility and solution-use notes

- Common cleaners/disinfectants: AlphaMop™ is published for applying and removing solutions, including disinfectants. Always align chemistry, dwell time, and residue control with the site SOP (especially in GMP and aseptic workflows).

- Solvent use: Texwipe literature for the AlphaMop™ pad/cover family references cleaning with solvents such as IPA and ethanol (and certain industrial solvents). If your area uses stronger solvents or oxidizers, qualify the full stack (pad + cover + handle/head) under your exact conditions before standardizing.

- Temperature exposure: A published AlphaMop™ pad/cover family note references use with temperatures below 400°F (205°C). For heat, autoclave, or hot-cycle programs, only use components explicitly rated for that process and document the qualification.

- Residue prevention: Overloading the mop can increase streaking and residue. Use measured wetting, controlled wringing, and a consistent stroke pattern; replace pads/covers before they become saturated with soil load.

QA/QC reference tables (published program-fit attributes)

Use these tables to support qualification planning, cleaning risk assessments, and controlled-environment documentation. Values shown are published configuration attributes (not site-specific performance guarantees).

| Attribute |

Published value |

Implementation note |

| Pad size |

8" x 15" (packed) |

Aligns with standard AlphaMop™ 15" x 8" head assemblies. |

| Packaging per inner bag |

25 pads + 4 fastening pins |

Supports staged introduction and inventory control by bag. |

| Packaging per case |

75 pads + 12 fastening pins (3 bags/case) |

Plan pad usage rate alongside cover change frequency and room zoning. |

| Sterility |

Non-sterile |

For sterile programs, use sterile equivalents that match the validated cleaning approach. |

| Cleanroom environment (published for AlphaMop™ family) |

ISO Class 3 – 7 (also referenced as Class 1 – 100,000; EU Grade A – D) |

Confirm with your site classification, gowning flow, and cleaning SOP. |

| Shelf life (published) |

Non-sterile: 5 years from date of manufacture |

Maintain FIFO and keep pads in original packaging until use. |

| Cleaning task |

Why the pad matters |

What technicians should watch |

| Disinfectant application/removal |

Improves uniform contact and helps maintain a consistent wet film on the surface. |

Streaking from over-wetting, saturated pads, or uneven wringing; replace pad/covers sooner. |

| Textured floors / epoxy with broadcast |

Cushion helps the cover conform into surface microtexture for more complete residue pickup. |

“Skipping” or missed valleys indicates compression set or pad shift; verify pins and replace pad. |

| Wall/ceiling cleaning |

Maintains contact while reducing localized pressure points that can cause streaks. |

Pad edge lift or snag risk; confirm full seating before going overhead. |

Common failure modes

- Streaking / uneven finish: Often caused by pad compression set, pad shift, or saturated mop media. Prevent with routine pad inspection, measured wetting/wringing, and faster change-out cadence in high-soil areas.

- Pad migration or corner lift: Triggered by incomplete pin seating or pin loss. Prevent with a pin check step and replacement of damaged pins; do not force a pad that no longer holds position.

- Residue carryover: Occurs when pads/covers are used beyond soil load capacity or moved between zones. Prevent with zone dedication, defined maximum coverage per pad, and “clean-to-dirty” room progression rules.

- Abrasion / particle generation from snagging: Can occur on sharp transitions, floor drains, or chipped coatings. Prevent by slowing at transitions, maintaining head angle control, and replacing pads that show tearing or edge wear.

- Static attraction (low humidity): In very dry conditions, some components can attract fines. Prevent by following site ESD/ionization controls and avoiding rapid rubbing against garments or dry wall panels.

Storage and handling best practices

- Keep pads in original, closed packaging until the moment of use; reseal opened bags if your SOP allows or discard per protocol.

- Store in a clean, dry cabinet away from corrugate, raw maintenance tools, and chemical vapors that can deposit residues on packaging.

- Avoid compressing pads in storage (stacking heavy items on top) to reduce premature compression set and uneven surface contact.

- Maintain FIFO by lot/date of manufacture to support shelf-life control and investigation readiness.

Documentation

SOS-hosted Texwipe datasheet (AlphaMop™ Cleaning System, Effective: December 2012):

Click HereTexwipe Technical Data Sheet (AlphaMop™ Series):

Click Here

If you have any questions please email us at Sales@SOSsupply.com or give us a call at (214)340-8574.

Check out the AI ChatBot powered by SOSCleanroom data libraries - give it a try!

THIS IS NEW FOR 2026!

Last updated: January 9, 2026.

© 2026 SOS Supply. All rights reserved.