Texwipe TX7105 Mini AlphaMop™ / Isolator Cleaning Tool™ Replacement Head Kit — 7" x 4" Head (Head Only)

TX7105 is a replacement head kit for Texwipe’s Mini AlphaMop™ / Isolator Cleaning Tool™ system used in isolators, glove boxes, biosafety cabinets, laminar flow hoods, and other small, hard-to-reach controlled-environment areas. This kit is intended for routine change-out to maintain a predictable cleaning geometry, preserve edge control, and keep your cleaning tool in spec as part of a disciplined contamination-control program.

For over 35 years, SOS and Texwipe have been close partners, and SOSCleanroom is the authorized Master Distributor of ITW Texwipe for the United States market. That relationship matters in critical environments: it supports continuity of supply, stable product lineage, and fast access to the manufacturer documentation your QA/QC team expects.

Published configuration (TX7105)

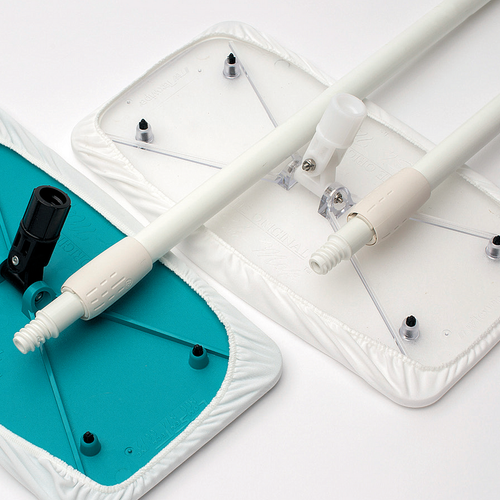

- System: Mini AlphaMop™ / Isolator Cleaning Tool™ (replacement head kit)

- Head size: (1) 7" x 4" (10 cm x 18 cm) thermoplastic mop head

- Pad: (1) polyester pad (padded head assembly for consistent surface contact)

- Fastening hardware: (2) fastening pins (as published)

- Packaging: 1 kit / case (1 mop head with attached pad, as published)

- Does not include: Handle(s) or mop covers

- SOSCleanroom selling unit: Case (1 mop head)

- Product type: Dry mop accessory / part

Low-linting performance starts with the cover — and a reality check

This replacement head kit is designed to support controlled cleaning with low particle and fiber generation when paired with appropriate Mini AlphaMop™ covers. Even so, no wiping or documentation material is truly “lint-free.” Treat mop covers, pads, and head assemblies as contamination-controlled components: control when they are opened, how they are transported, and what touches the working surface.

Where TX7105 fits in the Mini AlphaMop™ system

TX7105 replaces the mop head/pad assembly so operators can maintain predictable surface contact and edge control in tight spaces where wiping consistency matters more than mop size.

| Component |

What it does |

Notes for qualification |

| TX7105 replacement head kit |

Restores head geometry and padded contact surface for consistent cleaning pressure and corner control |

Head kit is non-sterile; select sterile covers/pads when sterility is required by the program |

| Compatible handles (not included) |

Provides reach and operator control for isolators and access ports |

Use handle length that preserves control (avoid over-reach that increases contact force and streaking) |

| Mini AlphaMop covers (not included) |

Primary cleaning substrate; drives sorption, low-linting behavior, and residue control |

Your cover choice should be aligned to chemistry (e.g., disinfectants/solvents), surface finish sensitivity, and residue risk |

Practical cleanroom use guidance (technicians and engineers)

- Change frequency is a control: The Mini AlphaMop™ concept supports frequent cover/pad changes to limit cross-contamination. Treat change-out as part of your cleaning protocol, not a convenience item.

- Use light, repeatable pressure: Excess pressure increases streaking, redeposition, and abrasion risk. Let the padded head and the cover do the work.

- Control edges and corners: Use deliberate corner passes. Avoid “digging” the head into gasket lines or welds, which can snag covers and generate debris.

- One-direction technique first: For critical surfaces, favor single-direction strokes and overlap lanes rather than scrubbing. If scrubbing is required, document it as an exception and re-clean with a controlled pass.

- Glove and saturation discipline: Wet gloves and over-wet covers are common drivers of residue films and streaks. Use only the minimum wetting needed for the chemistry and allow adequate dwell and dry time per your SOP.

Compatibility and wipe-down notes (what is published vs. what you must qualify)

TX7105 is a head/pad assembly. Chemical compatibility and residue performance are primarily governed by the cover material and your solution chemistry.

- Disinfectant/solvent compatibility: Align cover selection to the chemistry (e.g., alcohols, quats, sporicides) and qualify under your site conditions.

- Surface sensitivity: Rounded edges help with scratch prevention in tight corners, but operator pressure and trapped grit are still the primary scratch drivers. Control pre-cleaning and cover change-out frequency.

- Autoclave/sterility: TX7105 is published as non-sterile. If your program requires sterile introduction, use sterile components that are explicitly sterile-packaged and validated for your process.

- Qualification reminder: If your SOP requires routine external wipe-down of tools before entry (e.g., IPA wipe-down), qualify the assembled tool (head + handle + cover) to confirm no residue, no material degradation, and no unexpected particle shedding.

Cleanroom environment (as published for the Mini AlphaMop™ series)

| Published environment |

What it means operationally |

Practical control point |

| ISO Class 2 – 7 / Class 1 – 100,000 / EU Grade A – D |

Tooling is intended for use across a wide range of controlled environments when paired with appropriate covers and handling discipline |

Your facility’s introduction method (double-bag, wipe-down, pass-through, sterilization state) should be defined and audited |

| Shelf life: unlimited (mop heads/handles), as published |

Hardware can be stored long-term if packaging integrity and cleanliness are maintained |

Store clean, closed, and protected from abrasion; verify no dust loading before entry |

Common failure modes

- Streaking / film left behind: Often from over-wetting, insufficient dwell control, or using a cover that is not matched to the chemistry. Reduce solution load, change covers more frequently, and validate technique.

- Redeposition / cross-contamination: Driven by reusing covers past their control limit or touching non-controlled surfaces (cart handles, doors, glovebox exteriors) and returning to critical surfaces. Implement zone discipline and frequent change-outs.

- Snagging and cover damage: Typically caused by sharp edges, fasteners, or aggressive corner pressure. Use controlled corner passes and replace the head kit when geometry or edges degrade.

- Unexpected particles / shedding: Commonly from degraded pads/covers, poor storage (dust loading), or abrasion against rough surfaces. Keep components packaged until use and avoid dragging the head over rough transitions.

- Residue transfer: Often from wet gloves handling the cover or touching page/labeling materials and then returning to cleaning. Keep the cleaning tool as a “single-purpose” controlled item during the task.

Storage and handling best practices

- Keep the replacement head kit in original packaging until introduction into the controlled area.

- Store away from cardboard dust, maintenance debris, and high-traffic staging areas where surface loading can occur.

- Protect the head/pad surface from compression, abrasion, and tool-on-tool contact that can deform the pad or create scuffs.

- Before use, inspect the head edges and pad attachment for integrity; replace if damaged to avoid snagging and shedding.

Documentation

SOS-hosted Mini AlphaMop™ Technical Data Sheet (Effective: January 2013):

Click HereTexwipe Mini AlphaMop™ Series TDS (US-TDS-068, Rev. 11/21):

Click Here

If you have any questions please email us at Sales@SOSsupply.com or give us a call at (214)340-8574.

Check out our AI ChatBot powered by SOSCleanroom data libraries - give it a try!

THIS IS A NEW SOSCLEANROOM FEATURE FOR 2026!

Last updated: January 9, 2026

© 2026 SOS Supply. All rights reserved.