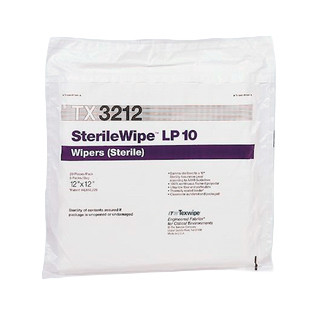

ITW TEXWIPE

Texwipe TX3212 SterileWipe LP10 12" x 12" Polyester Cleanroom Wiper

$681.74

- SKU:

- TX3212

- Availability:

- Stock Item

- Shipping:

- Calculated at Checkout

- Quantity Option (Case Only):

- 5 Bags of 100 Wipers Per Case

- Type:

- Dry Wiper

- Wiper Family:

- Vectra Alpha 10

- Wiper Material:

- Polyester

- Wiper Size:

- 12" x 12"

- Wiper Edge:

- Sealed Border

- Sterile:

- Yes

- ISO Class:

- ISO 2 (Class < 1)

- ISO Class:

- ISO 3 (Class 1)

- ISO Class:

- ISO 4 (Class 10)

- ISO Class:

- ISO 5 (Class 100)

- ISO Class:

- ISO 6 (Class 1,000)

- ISO Class:

- ISO 7 (Class 10,000)

- ISO Class:

- ISO 8 (Class 100,000)

Other Wipers We Recommend