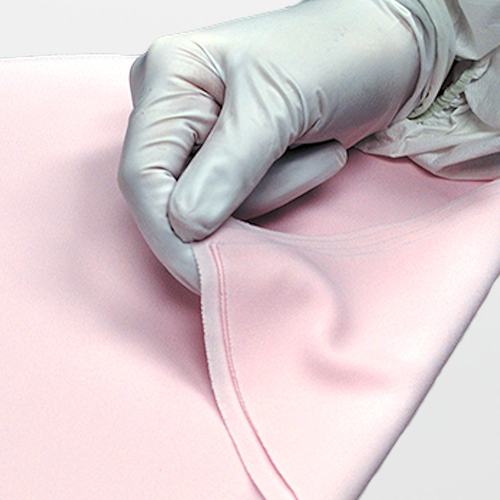

Product thumbnail shown for visual identification (color and edge style).

1) Practical solutions in a critical environment

A cleanroom wiper does two jobs at the same time: it physically moves particles/residue off a surface, and it either helps control or unintentionally creates

electrostatic charge while you wipe. Vision 1 Pink ESD 9" x 9" wipers are positioned for ISO Class 6 (Class 1000) work and ESD-sensitive handling, where

“good wiping” is less about scrubbing hard and more about controlling contact pressure, wipe geometry, and what happens to the soil you just picked up.

Note on language: no wiper is truly “lint-free.” In practice, the goal is low-linting behavior and predictable residue control when used with the right technique.

2) What is this wiper used for

- ESD-aware wipe downs of benches, fixtures, carts, and tooling in electronics assembly, PCB/PWB rework, and controlled environments.

- Removing light films and handling residues where a polyester knit wipe is preferred for durability and abrasion resistance.

- Color-coding and zone control (pink wipe = specific area/process) to reduce mix-ups in multi-room operations.

- General solvent-assisted wiping where the process uses compatible solvents/solutions (confirm compatibility with your specific chemistry and surface).

3) Why should customers consider this wiper

- ESD-focused workflow fit: marketed for ESD / anti-static environments where uncontrolled charge is a real defect driver.

- Durable knit polyester: designed to stay intact on edges, burrs, and fixtures that destroy softer wipes.

- Visual management: pink color supports zone control and contamination segregation by task or room.

- Traceability cues: sources describe lot-to-lot traceability and double-bag packaging (verify exact packout for your receiving spec).

- ISO class coverage: sources position the line for use across ISO 5–8, while this SOS SKU is listed for ISO Class 6.

4) Materials and construction

This product is described as an ESD / anti-static polyester knit wiper made from premium-quality virgin polyester fibers that are continuously filamented throughout the knit.

The continuous filament construction is commonly selected in cleanroom wiping to reduce fiber breakage compared with spun staple fibers, supporting low-linting performance when handled correctly.

Multiple sources describe additional processing steps such as cleaning/scouring and a proprietary cleaning process, plus inspection and traceability controls.

Because laundering status and packaging configurations can vary by sales unit, confirm the exact configuration against your receiving spec and the shipped case label.

5) Specifications in context

Attribute vs. this SOSCleanroom SKU

| Attribute |

SKU value / notes |

| SOSCleanroom product name |

VISION 1 PINK ESD Cleanroom 9" x 9" Wiper (ISO Class 6) |

| SOSCleanroom SKU (sales unit) |

VS10P-99U.150 (Bag) |

| Size |

9" x 9" |

| Material |

Polyester knit |

| ESD property |

Marketed as ESD / anti-static (ESD-safe workflow fit) |

| Cleanroom positioning |

Listed on SOSCleanroom as ISO Class 6 (Class 1000) |

| Color |

Pink |

| Laundered status |

SOS listing describes this SKU as “Un-Laundered.” Other published sources describe VS10P-99 as laundered. Treat laundering status as verify at receipt if it is a controlled requirement. |

| Bag count |

150 wipers per bag |

| Case configuration |

SOS sells case as 10 bags of 150 wipers (1,500/case). Other sources list 12 bags/case for a related VS10P item number. Confirm the “bottled” packout your warehouse expects. |

| Basis weight |

Not stated on the SOSCleanroom SKU page. Manufacturer product page for the Vision Pink line lists 115 gsm (treat as line data unless you confirm on the SKU documentation you receive). |

| Lead time (SOS listing) |

14–21 business days (as listed) |

6) Cleanliness metrics

For ISO-managed cleaning, “cleanliness” needs to be measurable. The most common documentation asks for ionic extractables (what can dissolve off the wipe into a test solvent)

and nonvolatile residue (NVR). If your QA program gates wipes by extractables, request the technical data/certificates for the exact item number you are buying.

Typical ion extractables

| Ion |

Typical value |

Notes |

| Na+, K+, Cl-, etc. |

Not published in source basis |

Request the lot-specific documentation if your process has ionic limits. |

Typical NVR

| Metric |

Typical value |

Notes |

| Nonvolatile residue |

Not published in source basis |

If you validate cleaning agents, confirm NVR expectations with the same solvent system you use in production. |

7) Packaging, sterility and traceability

- Sales unit options on SOS: Bag or Case.

- Bag unit (SOS): 150 wipers per bag.

- Case unit (SOS): 10 bags of 150 wipers per case.

- Sterility: not stated on SOS listing; manufacturer page describes the line as non-sterile.

- Traceability: sources describe lot-to-lot traceability and individual inspection. Confirm whether your shipped configuration includes lot labels on inner/outer bags.

- Double-bag packaging: described on manufacturer sources for the Vision Pink line (verify on receipt).

- Country of origin (manufacturer statement): not stated by the manufacturer for this SKU in the source basis. One distributor lists COO as “MY” for VS10P-99; if COO is a controlled requirement, verify via case label and/or lot documentation at receipt.

8) Best-practice use

The fastest way to burn through wipes (and still fail inspection) is wiping without a plan. In controlled environments, a wipe should have a start, a finish, and a “where did the soil go” answer.

Use the wipe as a controlled tool, not a rag.

Technique module (practical, operator-facing)

- Fold for control: fold into quarters (or eighths) to create clean “faces.” Assign one face per pass; don’t keep wiping with the same loaded area.

- One direction beats circles: wipe in straight, overlapping strokes (10–20% overlap). Circular wiping redistributes contamination.

- Pressure discipline: use consistent, moderate pressure. Overpressure can drive contamination into seams, fasteners, and texture.

- Edge awareness: keep cut edges away from critical optical faces or scratch-prone coatings unless the wipe is specifically qualified for that surface.

- Wet-to-dry logic: if using solvent, a controlled “wet pass” lifts residue; a follow-up “dry pass” (fresh face) removes solvent film before it dries down.

- ESD workflow basics: keep personnel grounded, avoid rapid “snap wiping,” and don’t wipe dry plastic at speed without controls—charge can build when humidity is low.

- Stop point: when the wipe face shows visible load or drag changes, stop and rotate to a clean face; “one more pass” is how contamination gets redeposited.

9) Common failure modes

- Redeposition: using the same wipe face too long moves contamination instead of removing it.

- Wipe “over-wet” halos: too much solvent leaves drying rings and pulls dissolved residue outward.

- Charge events: dry wiping at high speed, low humidity, or with poor grounding can spike ESD risk.

- Spec mismatch at receiving: packout (bags/case) or laundering status differs from what a work instruction expects—flag at receipt, not after it hits the floor.

- Unqualified chemistry: a solvent that is “fine on stainless” may haze plastics, swell coatings, or mobilize residues differently than expected.

10) Closest competitors

Competitor selection should be based on mechanism (knit vs. sealed edge, laundered vs. unlaundered, extractables documentation, and ESD behavior), not just price.

The closest alternatives are typically other polyester knit wipes positioned for cleanroom and electronics work.

- Texwipe AlphaWipe / Vectra-style polyester wipes: often chosen when tighter contamination control documentation, edge sealing, or ISO 3–5 positioning is required. Confirm COO and cleanliness metrics per SKU.

- Berkshire polyester knit cleanroom wipes: common in electronics and controlled environments; compare edge finish, laundering status, and extractables documentation to your acceptance criteria.

- Other High-Tech Conversions Vision series variants: same family, different ISO positioning and packaging; can be a near-swap when you need consistent material feel with adjusted cleanroom grade.

11) Critical environment fit for this wiper

This SKU is a practical fit when your environment is ISO Class 6-oriented and your defect risk includes both particulate/residue transfer and electrostatic sensitivity.

The pink color also supports zone control: you can dedicate pink wipes to a single line, room, or tool family and reduce cross-use mistakes.

If you are running tighter ISO classes, validating to strict extractables/NVR limits, or auditing laundering status, move the decision from “wipe description” to “documentation + incoming verification”:

request technical data/certificates for the exact item number, then confirm that the shipped configuration matches your controlled receiving spec.

12) SOSCleanroom note about SOP's

The Technical Vault is written to help customers make informed contamination-control decisions and improve day-to-day handling technique.

It is not your facility’s Standard Operating Procedure (SOP), batch record, or validation protocol.

Customers are responsible for establishing, training, and enforcing SOPs that fit their specific risks, products, equipment, cleanroom classification, and regulatory obligations.

Always confirm material compatibility, cleanliness suitability, sterility requirements, and acceptance criteria using your internal quality system and documented methods.

If you adapt any technique guidance from this entry, treat it as a starting template. Your team should review and approve the final method, then qualify it for your specific surfaces,

solvents, cleanliness limits, inspection methods, and risk profile. In short: use these best-practice suggestions to strengthen your SOPs—not to replace them.

13) Source basis

Primary product page

SOSCleanroom SKU page: https://www.soscleanroom.com/product/wipers/vision-1-pink-esd-cleanroom-9-x-9-wiper-iso-class-6/

Manufacturer product page

High-Tech Conversions (Vision Pink line): https://high-techconversions.com/product/vision-1-pink-esd-cleanroom-wipers/

Manufacturer PDF

High-Tech Conversions brochure (includes Vision Pink line card entries): https://res.cloudinary.com/iwh/image/upload/q_auto%2Cg_center/assets/1/26/High_Tech_Conversions_HTC_Brochure_2021_v3_0923.pdf

Supplemental published details (packout / COO references)

Hisco listing for VS10P-99 (includes COO “MY” and packaging statements): https://www.hisco.com/product/vs10p-99-23575

Standards and regulatory references

ISO: https://www.iso.org/standard/53394.html

FDA: https://www.fda.gov/

ASTM: https://www.astm.org/

IEST: https://www.iest.org/

SOSCleanroom is the source for this Technical Vault entry.

Briefed and approved by the SOSCleanroom (SOS) staff.

If you have any questions please email us at Sales@SOSsupply.com

Last reviewed: January 7, 2026

© 2026 SOSCleanroom