Cleaning a Cleanroom: What You Need to Know

28th Aug 2019

Even though a cleanroom is a space known for being highly regulated in order to prevent contamination, the room itself still needs regular maintenance and attention in order to keep what’s inside clean and sanitized. Whether it’s a weekly or monthly scheduled cleaning or the cleanroom is shut down for a thorough facility cleaning, having the right processes in place can ensure that the work being done inside the room is protected.

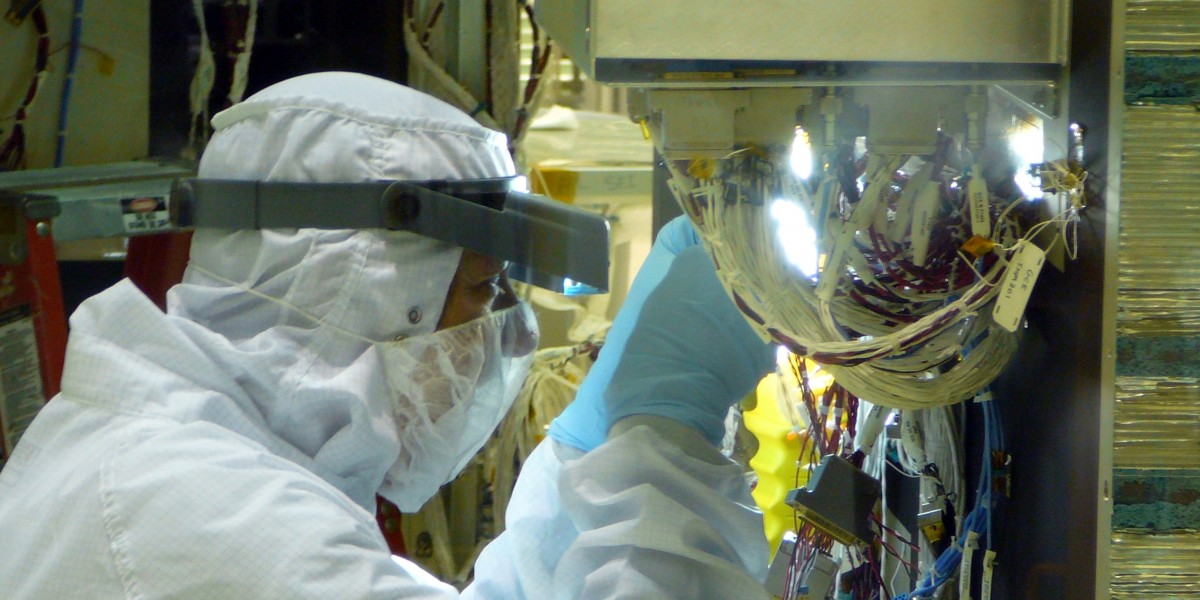

Contaminants in a cleanroom come from four major sources: environment, process, tools, and people. Contamination from people is the most common, so it’s important to have a strong training program to ensure any new staff are fully aware of their responsibilities. However, having an established process to prevent contamination from all of these sources is essential in saving both time and money. While each cleanroom will have its own process and will have different standards depending on the type of work being done, there are certain rules and regulations that can be used in any space.

At SOS Cleanroom, we provide a large collection of hard to find cleanroom supplies. Since 1981 we have supplied cleanroom products to government agencies, educational institutions, and a variety of other industries. What began with optical systems and technical lighting grew into supplying dozens of other products including swabs, apparel, gloves, gowns, sticky mats, and so much more. Whatever your needs are, you can count on SOS Cleanroom to provide the cleanroom supplies and custom products you need.

Cleanroom Maintenance Tips

Tools and Equipment

Rather than storing cleaning products outside the cleanroom, which requires the containers to be cleaned before entering the room, keep a set of tools and equipment inside the cleanroom. In order to clean the tools and equipment, even when they appear clean, the containers need to be washed with deionized water and special surface disinfectants before they enter the room and treated with non-shedding cleanroom wipes and isopropyl alcohol.

Wiping Surfaces

When cleaning a surface in a cleanroom, it’s not the same process as when you’re wiping down a spill on your kitchen countertops at home. To start, every surface, corner, and ledge are vacuumed and then wiped with a damp cleanroom wipe. Rather than using a back-and-forth or circular motion, wiping must be done in one direction only, either toward or away from the body. When wiping is done in any other way, it can produce more particles and contaminants than it removes. Each new stroke should use a clean surface of the wipe to prevent simply moving the particles around on the surface.

Air Filters

The airflow in a cleanroom is one of the more common ways that particles resurface in the air. Cleanrooms must use high-efficiency particulate attenuation (HEPA) filters. This will ensure the highest number of particles are removed from the room. Ionizing grids are also used to prevent static from attracting particles. To ensure that the air filters are working efficiently and effectively, they should be vacuumed every three months to remove particles. Ionized grids should be cleaned every six months. In addition, it’s also important to pay attention to the time of year. Spring and fall seasons will see an increase in outdoor particles.

Preventing Grease From Spreading

There are also special processes in place for cleanrooms with machinery that require grease. These pieces of machinery are separated with polycarbonate shields that will prevent the spread of grease and limit its airborne molecular contamination (AMC). Maintenance personnel will wear three pairs of latex gloves and, after greasing the equipment, will remove the outermost glove, turning it inside out. This will ensure that grease is not dripped on the floor or door handles are not covered in grease.

Particle Counters

Cleanrooms may utilize surface or air particle counters. These can automatically check levels of particles in the air at set intervals and at various locations throughout the space. They are often placed at tabletop height, near moving conveyor belts, and at workstations — wherever the most movement is taking place.

These are just a few cleanroom maintenance tips that will help ensure your cleanroom is as clean as possible. The important thing is that new employees are thoroughly trained, the process is always consistent, and that the environment is regularly monitored for any changes.

SOS Cleanroom provides cleanroom supplies for all types of purposes and ISO Classifications. Whatever your needs are, you can count on us to provide superior service and the best cleanroom products.