Cleanroom Mops Polyester & Microfiber Mop Heads, Sterile Systems, Frames & Handles Includes zone segregation discipline, wet-contact-time guidance, residue control, single-use vs validated laundering, sterile transfer expectations, and a visual mopping SOP for ISO 5–8. ▼ EXPAND GUIDE (click here to open)

Category Overview

Cleanroom Mops

Polyester & Microfiber Mop Heads, Sterile Systems, Frames & Handles

Low-Shedding Residue Control Sterile Options Validated Programs

Cleanroom mops are contamination-control tools used on floors, walls, ceilings, and large surfaces in controlled environments. Proper selection depends on matching mop head material, construction, solution compatibility, sterility requirements, frame/handle design, and strict adherence to SOP discipline to your process.

Best suited for: ISO 5–8 cleanrooms and controlled support areas. Mop systems may also be used in more critical zones when defined by facility SOP and contamination control program.

Common cleanroom mopping applications:

- Routine floor cleaning in ISO-classified environments

- Wall and ceiling cleaning in controlled production zones

- Application of disinfectants and sporicides (per SOP)

- Residue-sensitive cleaning in semiconductor and optics facilities

- Defined cleaning rotations in aseptic processing programs

Cleaning program structure (what “controlled” means)

- Cleaning: removes soils and residues so disinfectants can perform as intended.

- Disinfection: requires validated chemistry and maintained wet contact time.

- Sporicidal steps: used on defined schedules or risk-based intervals per SOP.

- Follow-on actions: some disinfectants/sporicides may leave residues; follow SOP for any required secondary wipe or rinse step.

ISO 5–6 controlled zones

→ Low-shedding polyester or validated microfiber systems

Aseptic ISO 5 environments

→ Sterile mop systems with controlled transfer packaging

Higher liquid capacity needs

→ Microfiber or tube/looped systems (per SOP)

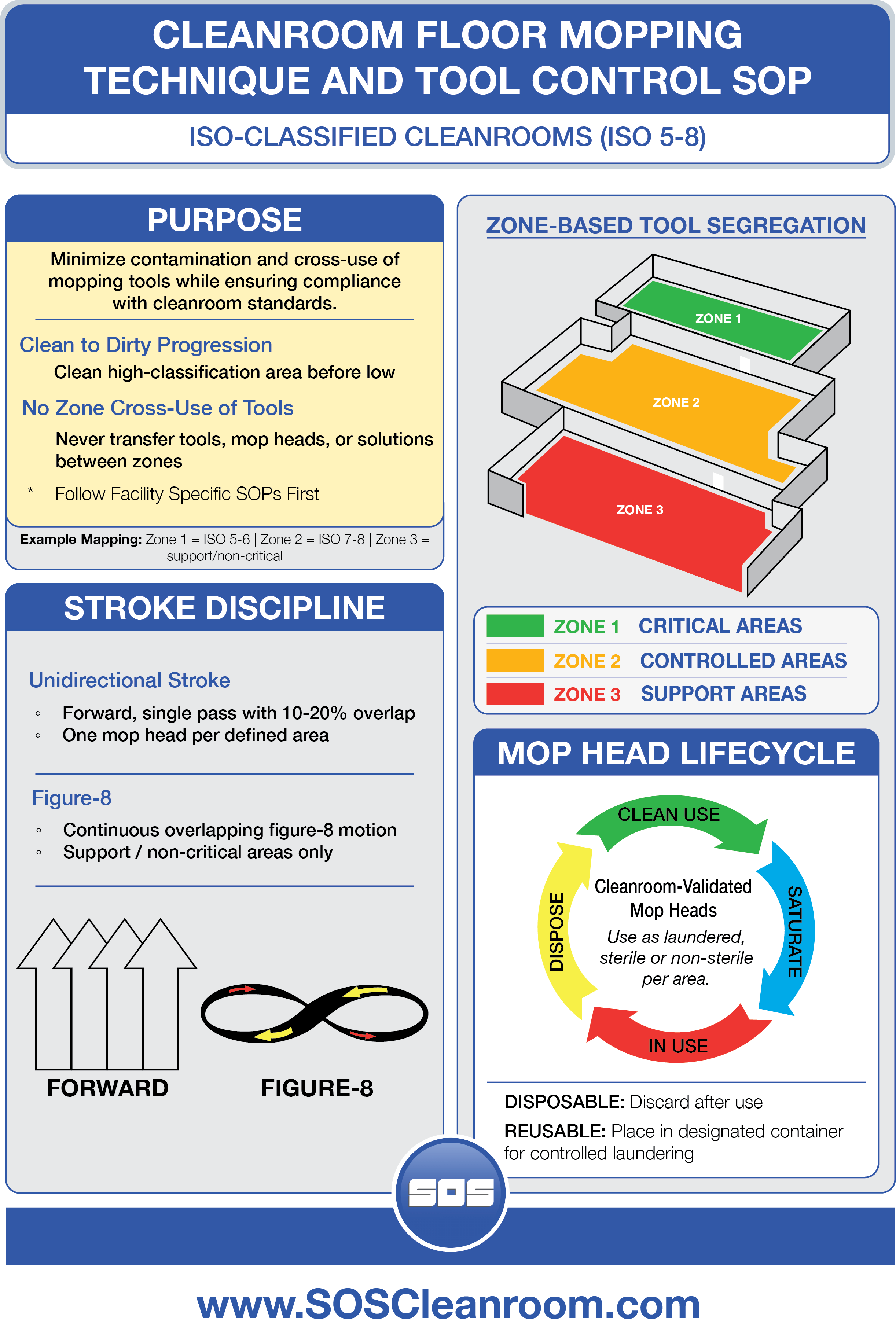

Visual SOP Reference

Cleanroom Floor Mopping Technique & Tool Control SOP (ISO 5–8)

Use this visual as a training aid for zone segregation, stroke discipline, and mop-head lifecycle control. Your facility SOP (and validated cleaning program) always governs.

What this SOP visual covers: clean-to-dirty progression, no zone cross-use of tools/solutions, unidirectional stroke vs figure-8 guidance, and mop head lifecycle control (saturate → in use → dispose / controlled laundering).

Key takeaways:

- Zone segregation: dedicate mop heads, frames, handles, and buckets by zone; never transfer between zones.

- Stroke discipline: use a consistent technique with overlap to minimize redeposition and ensure uniform coverage.

- Mop head lifecycle: define change-out triggers by area, visible soil, streaking, loss of glide, or SOP schedule.

- Wet contact time: disinfectants/sporicides must remain wet for the full validated contact time to be effective.

Mop head materials & construction

- Polyester knit: durable and low-shedding when properly constructed.

- Microfiber: can improve pickup; performance depends on fiber design and validated laundering or disposal controls.

- Sealed-edge construction: reduces loose fibers and fraying at edges.

- Single-use vs laundered: laundering must be validated to prevent cross-contamination; higher-risk areas often use limited-use or sterile formats.

Mop system types

- Flat mop systems: controlled contact and consistent coverage; widely used in cleanrooms.

- Tube/looped heads: increased liquid capacity where shedding and control requirements are met.

- Pre-saturated systems: reduce operator variability and limit bucket contamination risk.

- General-purpose string mops: typically avoided in critical cleanroom environments due to control limitations.

Application methods & contamination control

- Pre-saturated mop heads: consistent solvent load and reduced cross-contamination risk.

- Controlled dosing systems: help maintain consistent solution concentration and application volume.

- Two-bucket method: separates clean solution from rinse solution to reduce redeposition.

- Dedicated buckets per ISO zone: prevents cross-contamination between areas.

- Wringing control: avoid uncontrolled wringing; it changes concentration and can redeposit soils. Use defined dosing or approved wringing tools per SOP.

- Never re-dip used heads into clean solution.

- Do not “top off” containers: never add fresh solution into a container with used or uncertain contents.

Solution compatibility, residue control & surface protection

- Commonly used with: IPA, ethanol, disinfectants, and sporicides (verify compatibility per manufacturer guidance and SOP).

- Surface compatibility: confirm fit for floor coatings and sealants (epoxy/urethane/vinyl), metals (stainless), and cleanroom polymers to avoid damage, haze, or corrosion risk.

- Residue control: excessive liquid and some chemistries can leave films; follow SOP for any required follow-on wipe or rinse step.

- Maintain wet contact time: disinfectants must keep the surface wet for the full validated contact time to be effective.

Zone segregation, labeling & change-out discipline

- Dedicated by zone: use separate mop heads, frames, handles, and buckets for each ISO classification or production zone.

- Label tools clearly: zone-label handles/buckets and prevent cross-use during shift changes.

- Change-out triggers: replace mop heads after defined area coverage, visible soil, drying/streaking, loss of glide, or SOP schedule.

- Event response: change heads immediately after spills, high-risk tasks, or excursions.

Sterile vs cleanroom-packaged mop systems

- Sterile mop heads: used in ISO 5 and aseptic environments when required by SOP.

- Controlled transfer packaging: double-bag or validated packaging supports sterile introduction and staging control.

- Cleanroom-packaged: controlled for particulates and handling but not sterile.

- Traceability: confirm sterility labeling (if required), lot numbers, and expiration dating expectations per your quality system.

Frames & handles

- Material selection: stainless steel or compatible polymers resistant to cleaning chemistries.

- Smooth geometry: minimizes contamination traps and supports effective wipe-down.

- Swivel control: improves consistent contact along edges and under equipment.

- Sterile compatibility: required for aseptic transfer protocols and staging discipline.

Best-practice mopping technique (SOP fundamentals)

- Work from clean-to-less-clean areas and from farthest point toward exit.

- Use controlled S-stroke or figure-8 pattern (per SOP) with consistent overlap.

- Maintain the leading edge forward to reduce redeposition.

- Maintain surface wetness for full disinfectant contact time; do not allow premature drying.

- Use “one head per defined area” discipline when required; change heads early rather than pushing contamination.

- If SOP requires, follow disinfectant/sporicide steps with the approved follow-on wipe or rinse action.

- Avoid stepping on cleaned areas before drying.

For the fastest recommendation, be ready to share: ISO class/zone, floor type/coating (epoxy/vinyl/urethane), chemistry used (cleaner/disinfectant/sporicide/IPA), sterility requirements, area size & frequency, and whether your program uses single-use or validated laundering.

SOSCleanroom supports over 2,500 active cleanroom clients across semiconductor, pharmaceutical, medical device, aerospace, optics, and advanced manufacturing sectors.

Need help selecting?

Talk to a cleanroom specialist

Email Sales@SOSsupply.com or call (214) 340-8574.

SOSCleanroom Disclaimer

Mop system performance depends on environmental classification, solution chemistry, surface composition, operator technique, saturation control, and adherence to validated SOPs. Customers are responsible for verifying compatibility, sterility requirements, and regulatory compliance. Always reference current manufacturer documentation, SDS, and approved quality procedures. Specifications may change without notice.