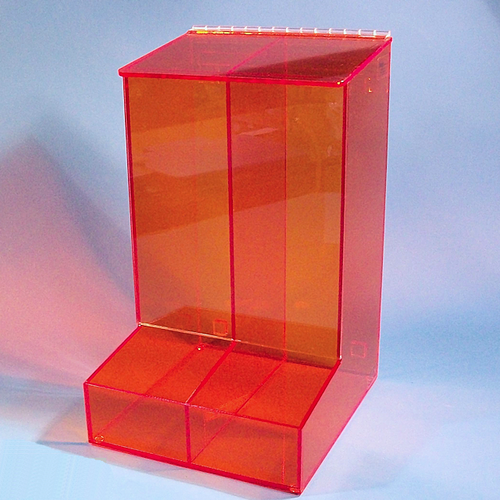

15.5"W x 24"H x 10.5"D Cleanroom Apparel Dispenser — Coverall / Lab Coat / Frock Station

Cleanroom garments protect your process only when they remain organized, covered, and introduced consistently. When coveralls or lab coats are staged loosely on shelves or carts, you typically see the same outcomes: excessive handling, crushed packaging, mix-ups between sizes, and “one-off” substitutions that quietly erode gowning discipline.

This 1-compartment apparel dispenser is designed to dispense coveralls, lab coats, frocks, smocks, aprons, and similar folded apparel from a defined, wall-mounted location. You are not just storing garments — you are controlling how they are accessed, which reduces unnecessary waste and supports repeatable gowning behavior across shifts. :contentReference[oaicite:0]{index=0}

Published configuration (AD-001/101)

- SKU: AD-001/101

- Overall size: 15.5"W x 24"H x 10.5"D

- Compartments: 1

- Designed for: Coveralls, lab coats, frocks, smocks, aprons, etc.

- Material options: 1/4" clear acrylic or 1/4" clean PETG (PETG noted as safe with IPA)

- Front options: Open front or closed front; with or without lid

- Mounting: Wall-mount or free-standing (rubber pads to help prevent slipping/scratching)

- Hardware: Heavy-duty wall mount bracket included (support bar, instructions)

- Finish: Flame-treated edges for smoothness

- Packaging: Poly bag, 1 per case

- Availability: Made to Order, 14–21 Business Days

:contentReference[oaicite:1]{index=1}

Why dispensers reduce contamination risk and unneeded waste

An apparel dispenser reduces the number of times garments are touched before use, keeps packaging from being crushed or torn, and prevents “pile staging” on benches. Operationally, that drives fewer mis-picks, fewer damaged packs, and fewer uncontrolled garment changes — all of which translate directly into less waste and more consistent gowning outcomes.

Material selection: Acrylic vs PETG

Choose the dispenser material based on how your facility cleans wall fixtures:

- Acrylic: Ideal when the environment does not require cleaning dispensers with IPA or harsh chemicals; acrylic is highly scratch-resistant and is cleaned with soap and water.

- PETG: Selected for compatibility with IPA and other harsh chemicals (a common requirement in drug manufacturing, biotech, and some medical device programs).

:contentReference[oaicite:2]{index=2}

Fixture longevity checkpoint

If routine IPA wipe-down is part of your SOP for dispensers and adjacent fixtures, PETG is typically the safer selection for long-term durability.

Build the complete gowning station

Apparel to stage inside (Kimtech)

Wipers (Texwipe) — keep the station clean

- Texwipe TX1009 AlphaWipe® 9" x 9" Use qualified cleanroom wipers for touch-point wipe-downs per your SOP (avoid improvised paper products around gowning infrastructure).

Placement and restock guidance

- Mount where the garment is donned: gowning bench boundary, airlock entry, or just before the controlled corridor.

- Post a simple label: garment type + size range + room/zone + revision date (helps prevent “borrowed” inventory).

- Define a par level: keep only what is intended for the shift/day at point of use; hold reserves in controlled storage to prevent over-handling.

- Protect packaging integrity: damaged garment packaging is a frequent source of waste and rework — dispensers reduce crushing and scuffing.

Important notes

Dispenser ships as the fixture only. Items shown in images (gloves, bouffants, wipers, apparel) are not included. Photos may not represent the selected material type; acrylic is typically very clear while PETG may have a slightly darker tint. :contentReference[oaicite:3]{index=3}

If you have any questions please email us at Sales@SOSsupply.com or give us a call at (214)340-8574.

Check out the AI ChatBot powered by SOSCleanroom data libraries - give it a try!

THIS IS NEW FOR 2026!

© 2026 SOS Supply. All rights reserved.