S-CURVE

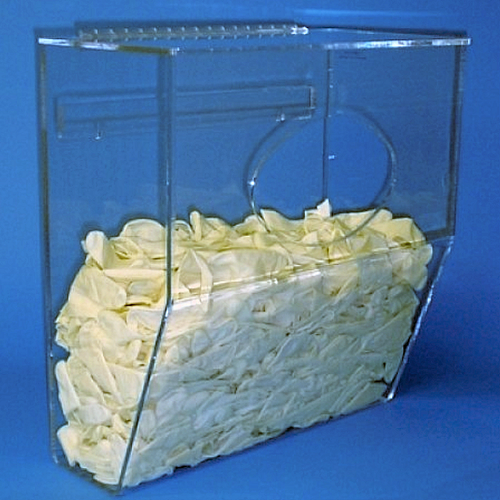

16.5"W x 17"H x 12"D - Cleanroom Dispenser with Front Opening (Tapered Design)

$300.00

- SKU:

- SBD-19-PETG

- Availability:

- Made to Order, 14 - 21 Business Days

- Shipping:

- $25.00 (Fixed Shipping Cost)

- Quantity Option (Each):

- 1 Dispenser