Medipak

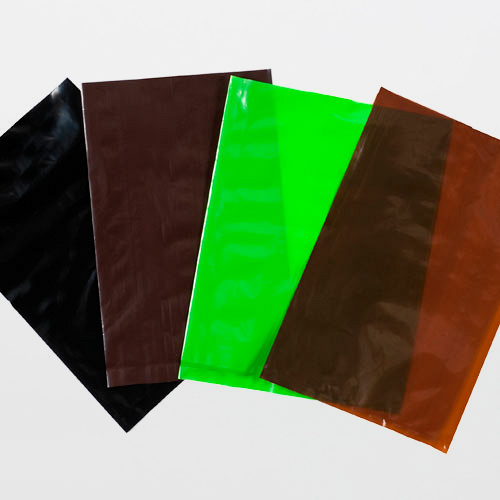

Medipak UVLI Tubing Cover

$46.20

- SKU:

- UVLI Tubing

- Availability:

- 1 - 2 Weeks

- Shipping:

- Calculated at Checkout

- Quantity Option (Case):

- See in Size Dropdown