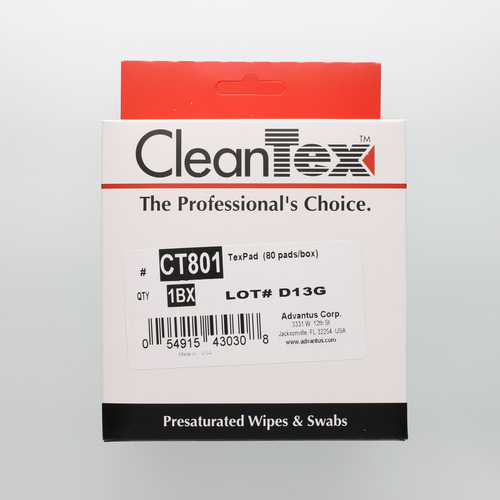

CleanTex

CT801 Tex Pad Tape-Head Cleaner

$22.19

- SKU:

- CT801 BOX

- Availability:

- Stock Item

- Shipping:

- Calculated at Checkout

- Quantity Option (Box):

- 80 Pads

- Quantity Option (Case):

- 10 Boxes of 80 Pads (800 Pads)