When a Mop Is Only as Good as Its Interface: Why TX7150 Matters More Than Most Teams Expect

The Technical Vault | By SOSCleanroom

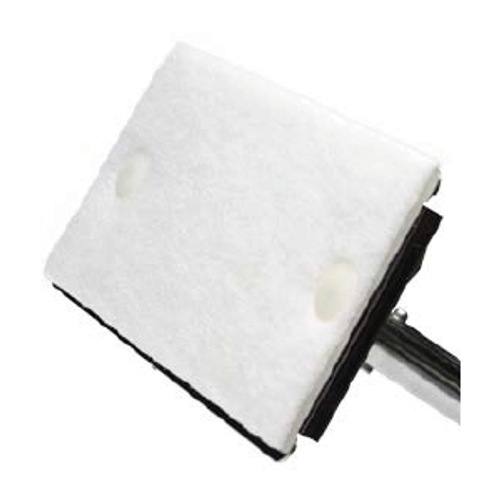

Texwipe TX7150 TexMop™ Replacement Polyester Pad Kit (Non-Sterile) is not an accessory—it is the mechanical interface that determines whether a flat-mop system behaves like a controlled cleaning tool or a pressure-inconsistent swab on a stick.

In the TexMop workflow, the pad kit is what allows a 9" × 9" wiper to conform to surfaces, maintain consistent contact, and remain stable through directional strokes—especially on walls, ceilings, corners, and other geometry where uncontrolled flex creates skipped zones and redeposition risk.

TX7150 is supplied as 8" × 4" polyester pads with white fasteners, packaged as 10 double-bagged sets per case (each set includes 10 pads and 4 fasteners).

What TX7150 Is For

TX7150 is designed for facilities using the TexMop™ flat-mop system with 9" × 9" cleanroom wipers, where cleaning effectiveness depends on repeatable contact pressure and fast, frequent wiper changes.

Teams rely on TX7150 when they need to apply and remove cleaning or disinfecting solutions without chatter, uneven loading, or skipped zones—and when operator discipline (fresh wipe surfaces, directional strokes, controlled wetness) must be maintained during high-frequency cleaning.

Decision Drivers

- Contact control: pad stability that keeps the wiper engaged across flat surfaces and transitions.

- Change-out discipline: fastener-based attachment enables frequent wiper replacement.

- Packaging discipline: double-bagging supports staged entry and predictable consumption.

- Program fit: supports ISO Class 3–8 / EU Grade A–D environments as part of the TexMop system.

- Sterile pathway: sterile pad option (STX7150) available for workflows requiring sterile components.

Materials and Construction, Explained Practically

TX7150 uses polyester pads because polyester is dimensionally stable, chemically compatible with common cleanroom solutions, and resistant to fiber breakdown under pressure.

The pad itself is not the cleaning media—the wiper is. TX7150 functions as the compliance layer between the hard mop head and the wiper, allowing the wiper to track surface micro-variations instead of bridging over them. This improves surface contact while reducing the tendency to scrub harder, which is a common driver of particle generation and streaking.

Cleanroom Reality Check: There Is No “Lint-Free” System

No wiper or mop system is truly lint-free. The control question is whether the selected pad–wiper–method combination is low-linting enough for the step and whether technique prevents redeposition. TX7150 contributes indirectly by improving contact stability and reducing pressure variability, which lowers the chance of mechanical shedding.

How TX7150 Fits into Cleaning and Disinfection Workflows

Cleaning fails when contact is uneven and pressure varies; disinfection fails when wet film coverage and dwell time are inconsistent. Texwipe positions the TexMop system for ceilings, floors, walls, isolators, hoods, and confined areas—exactly where interface stability prevents skip lines and uneven solution application.

Best-Practice Use

- Use directional, overlapping strokes (often ~50% overlap).

- Work from cleaner zones toward less-clean zones.

- Rotate to fresh wiper surfaces early and often.

- Treat frequent change-out as contamination control—not waste.

- Segregate clean and used solutions to prevent reintroduction of soils.

Many programs adopt a two-stage approach: an initial absorbent or higher-loading wipe for soil removal, followed by a lower-linting synthetic wipe for final passes. TX7150 enables this by making wiper swaps fast enough that teams actually do them.

“Made in the USA” Context That Matters

For many controlled-environment programs, U.S. manufacturing is a proxy for supply assurance, traceability expectations, and manufacturing oversight. Texwipe’s U.S. footprint—anchored in North Carolina and supported by documented manufacturing expansion—matters when a cleaning tool becomes a process control rather than a convenience item.

Closest Competitors

Contec Cleanroom Mopping Systems

Disposable pads and covers positioned for controlled-environment cleaning with emphasis on change-out discipline.

Berkshire Disposable Cleanroom Mop Pads

Synthetic pad formats used where mop consumables are tightly managed as part of contamination control.

Micronova Mop Systems

Flat-mop ecosystems designed for controlled application of disinfectants and routine cleanroom maintenance.

Where TX7150 Sits in a Controlled Cleaning Program

TX7150 is the interface that makes TexMop a system rather than a handle-and-wipe combination. When consistent contact, fast change-out, and directional discipline matter, the pad kit quietly becomes one of the most important contamination-control components in the room.

Source Basis

- SOSCleanroom product page: Texwipe TX7150 TexMop Replacement Polyester Pads.

- Texwipe TexMop™ Technical Data Sheet.

- Texwipe manufacturer product page: TX7150 and TexMop system.

- Public manufacturing footprint references: North Carolina Department of Commerce.

- Competitor references: Contec, Berkshire, and Micronova cleanroom mopping systems.