ITW TEXWIPE

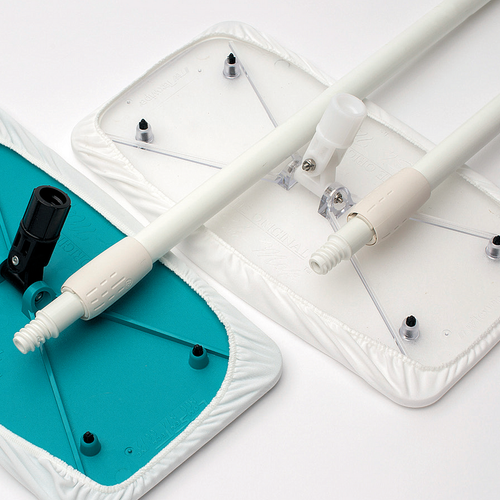

Texwipe TX7113 ClipperMop 11" Replacement Head (HEAD ONLY)

$160.02

- SKU:

- TX7113

- Availability:

- 10 - 14 Business Days

- Shipping:

- Calculated at Checkout

- Type:

- Dry Mop

- Quantity Option (Each):

- 1 Head