Reducing Streaks on Large Surfaces: Why 12" x 12" Polyester Wipers Improve Coverage and Technique Consistency

The Technical Vault

By SOSCleanroom

ISO 14644-5 Operations

Large-Surface Wipe Control

Damp-Film Solvent Technique

Residue & Rework Reduction

Operator Technique Control

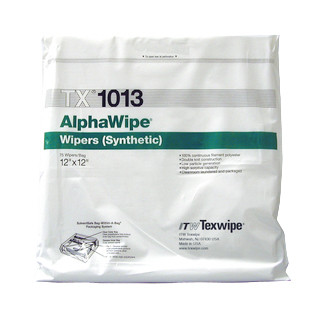

Texwipe TX1013 AlphaWipe® (12" x 12") — what this polyester wiper is designed to control

Texwipe TX1013 AlphaWipe® is a 12" x 12" cleanroom polyester wiper commonly selected for

larger-surface wipe-downs where method consistency and coverage are the primary controls. The 12" x 12" format

supports a more stable fold geometry and provides additional usable wiping area per wiper, which can reduce the tendency

for operators to overuse a loaded wiping face.

Many visible defects during wipe-down (streaks, haze, and “cleaning lines”) occur because wetness, stroke overlap, and

clean-face rotation discipline drift during large-area cleaning. TX1013 is used to make the method easier to execute consistently:

more surface area, more controlled folds, and fewer forced “extra passes” with a partially loaded wiper.

Operations takeaway: If technicians are struggling with streaks on benches, panels, doors, carts, and large tool covers,

the solution is often method control + proper wipe format, not “more solvent.”

ISO-first context: wipe-downs must be standardized to be repeatable

ISO 14644-5 treats cleaning as an operational control based on defined methods, trained personnel practices, and controlled materials.

A wiper is a process tool: its size, construction, and handling controls influence re-deposit, particles, and residue behavior.

When large-surface wipe-down is part of routine operations, the wipe pattern, overlap, wetness target, and change-out triggers

should be written and trained in the SOP to reduce operator-to-operator variability.

For USP-influenced environments, the same concept applies—cleaning steps must be repeatable and documented. Even for non-sterile wipe-down,

applying method discipline prevents “looks clean” outcomes that fail under inspection or environmental monitoring scrutiny.

Technical data summary (reference — consult current manufacturer TDS for controlled programs)

| SKU |

TX1013 |

| Wiper family |

AlphaWipe® |

| Construction |

Polyester cleanroom wiper |

| Size |

12" x 12" |

| Sterility |

Non-sterile (select sterile variants where sterility/transfer controls are required) |

Receiving control tip: For controlled programs, verify the correct size and case configuration at receiving and capture lot codes per SOP.

Large-format wipers are sometimes substituted with smaller sizes, which can unintentionally change method behavior.

Best-practice wipe-down method for large surfaces (operator-procedure level)

Best practice begins with a consistent fold. A 12" x 12" wiper allows a stable fold geometry that can be repeated across operators and shifts.

Open the package only when ready to wipe, remove one wiper at a time, and avoid contact between the wiping face and gloves, garments, benches, or carton edges.

If solvent is used, apply it to the wiper to reach a controlled damp condition rather than flooding the surface; uncontrolled wetness is a primary driver of streaking.

Wipe using straight, overlapping strokes in one direction, maintaining an overlap pattern so no “skip lanes” remain. Rotate to a clean wiping face after each pass and

define a maximum surface area per face in the SOP if the process is defect-sensitive. Replace the wiper immediately if it becomes loaded, tacky, or begins leaving visible

artifacts. For edges, corners, and seams where a flat wiper cannot maintain controlled contact, transition to a swab rather than forcing the wipe into tight geometry.

Where residue sensitivity is high, a two-step method can improve outcomes: a first damp pass to mobilize soils followed by a second clean pass to remove dissolved material

before it dries into a film. These steps should be trained and periodically observed to prevent method drift.

Typical cleanroom failures and how to avoid them (ISO & USP perspective)

- Streaking / tide marks: Usually over-wetting, backtracking, or reuse of a loaded face. Prevention: damp-film control, one-direction strokes, and clean-face rotation (ISO 14644-5).

- Haze after drying: Often redeposit of dissolved contamination. Prevention: smaller sections, earlier change-out, and second-pass pickup where needed.

- Skip lanes on large surfaces: Inconsistent overlap patterns. Prevention: defined wipe pattern and overlap rules (ISO 14644-5).

- Particles after “cleaning”: Handling contamination or excessive pressure. Prevention: handle-only discipline and controlled pressure (ISO 14644-5 personnel practices).

- Method drift between shifts: Different outcomes with the same wiper. Prevention: define wetness target, stroke pattern, and change-out triggers; train and audit (ISO 14644-5).

- Non-sterile use in sterile workflows: Creates program non-conformance. Prevention: sterile products and transfer controls where required (USP concepts).

Suggested companion products and technical rationale

SOSCleanroom suggests the following companion items to keep the wipe method controllable across operators and shifts. These selections support controlled wetness

(chemistry), access control (swab), and personnel contamination control (gloves). Links are provided for convenient internal reference.

Defensible pairing principle: The wiper controls coverage and pickup behavior; the solvent controls solvency and drying behavior;

the swab controls access without glove intrusion; and the glove controls operator-introduced contamination.

Disclaimer

This Technical Vault content is provided for general operational guidance and procurement planning only. It does not replace facility SOPs,

validation protocols, quality risk assessments, environmental monitoring programs, or manufacturer documentation (TDS/SDS/label instructions).

Always follow applicable ISO standards, USP chapters, and site-specific procedures. TX1013 is non-sterile; if sterile presentation/transfer is required,

select sterile products and follow your facility transfer procedures and documentation controls.

Questions? Email Sales@SOSsupply.com or call (214) 340-8574.

© 2026 SOSCleanroom. All rights reserved.