ITW TEXWIPE

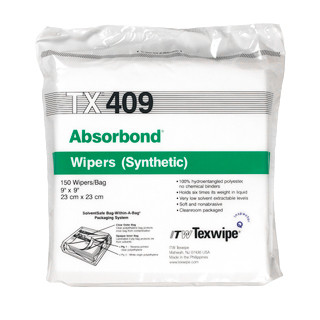

Texwipe TX409 Absorbond 9" x 9" Polyester Cleanroom Wiper

$64.39

- SKU:

- TX409 BAG

- Availability:

- Stock Item

- Shipping:

- Calculated at Checkout

- International Shipping::

- Available for this product

- Quantity Option (Bag):

- 300 Wipers Per Bag (2 Inner Bags of 150 Wipers)

- Quantity Option (Case):

- 10 Bags of 300 Wipers Per Case

- Type:

- Dry Wiper

- Wiper Family:

- Absorbond

- Wiper Material:

- Polyester

- Wiper Size:

- 9" x 9"

- Wiper Edge:

- Cut Edge

- ISO Class:

- ISO 5 (Class 100) - ISO 8 (Class 100,000)

- Country of Origin::

- Made in USA